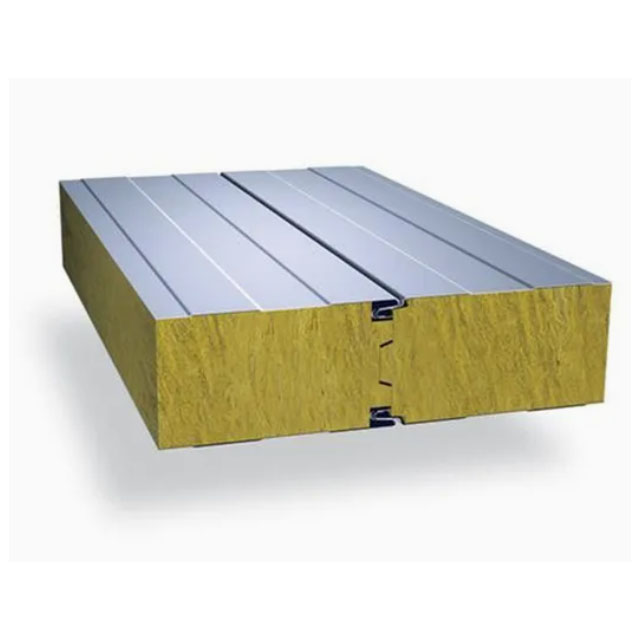

Rockwool Wall Panel

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

With green building trends rising, Rockwool Wall Panels are key innovations. Featuring metal-polyurethane load-bearing structures for insulation and structural integrity, they offer high-performance fire resistance and soundproofing. Modular design simplifies installation/maintenance, while waterproof/fireproof features enhance durability. A versatile sustainable solution for modern green architecture.

Characteristics

Color Selection

Uncover a dynamic range of steel sheet color options! From the refined subtlety of ivory and beige to the spirited allure of emerald green and lime, and the bold magnetism of raspberry and hot pink, our extensive color palette caters to every aesthetic inclination. Boasting a broad collection of both timeless and distinctive shades, we streamline the process of selecting the perfect color to flawlessly align with your design visions and project needs.

Certifications

Our company holds CE, ISO 9001, SGS, and FM certifications, ensuring compliance with EU standards, rigorous quality management, strict testing, and fire safety norms. These credentials reflect our commitment to excellence, reliability, and industry leadership.

Rockwool wall panels are advanced insulation and fire-resistant building materials widely used in residential, commercial, and industrial construction. Known for their thermal insulation, acoustic performance, and fire resistance, these panels combine rockwool (mineral wool) cores with various facings to deliver a high-performance wall cladding solution.

This article provides a detailed technical overview of rockwool wall panels, covering material composition, engineering principles, industry standards, regulatory requirements, installation best practices, and maintenance guidelines to help architects, engineers, and contractors make informed decisions.

What Are Rockwool Wall Panels?

Rockwool wall panels consist of a core made from rockwool insulation fibers, sandwiched between facing layers such as galvanized steel, aluminum, or coated steel sheets. These panels are designed to provide thermal insulation, fire protection, and sound attenuation while also serving as a durable exterior or interior cladding.

Material Composition and Engineering Principles

Core Material: Rockwool (Mineral Wool)

Composition: Made from natural basalt rock and recycled slag spun into fibrous wool.

Properties: High melting point (~1,000°C), non-combustible, low thermal conductivity (typically 0.034–0.040 W/m·K).

Density: Typically ranges from 80 to 180 kg/m³ depending on application.

Fire Performance: Classed as A1 non-combustible under EN 13501-1.

Facing Materials

Galvanized Steel: Common for exterior panels; thickness ranges from 0.4 mm to 0.7 mm.

Aluminum or Aluminum Composite: Lightweight and corrosion resistant.

Coatings: Polyester, PVDF, or PE coatings for enhanced weather resistance and aesthetic options.

Panel Construction

Core thickness varies from 30 mm to 150 mm depending on insulation requirements.

Panels typically feature tongue-and-groove or shiplap edges for secure jointing.

Panels can be manufactured in sizes up to 1200 mm width and lengths up to 12 meters.

Key Technical Characteristics

| Parameter | Typical Value/Range |

|---|---|

| Thermal Conductivity | 0.034 – 0.040 W/m·K |

| Fire Rating | Euroclass A1 (non-combustible) |

| Sound Insulation | Rw up to 50 dB depending on thickness |

| Density | 80 – 180 kg/m³ |

| Panel Thickness | 30 mm to 150 mm |

| Facing Thickness | 0.4 mm – 0.7 mm steel/aluminum |

| Water Absorption | ≤ 1% (EN 1609) |

Industry Standards and Regulatory Compliance

EN 13162: Specification for mineral wool insulation products.

EN 13501-1: Fire classification of construction products.

EN 14509: Self-supporting double skin metal-faced insulating panels.

ASTM C612: Mineral fiber block and board thermal insulation.

ISO 9001: Quality management systems in manufacturing.

LEED / BREEAM: Certifications supporting sustainable construction.

Engineering and Installation Considerations

Design & Structural Integration

Rockwool panels can be load-bearing or non-load bearing; consult structural engineers.

Compatible with steel, concrete, or timber framing.

Ensure panel joints are sealed with fire-resistant sealants to maintain integrity.

Installation Best Practices

Handle panels with care to prevent damage to facings.

Install vapor and weather barriers as required by local codes.

Fastening using self-drilling screws with appropriate washers recommended.

Maintain panel alignment and ensure expansion gaps for thermal movement.

Verify insulation continuity at panel joints to avoid thermal bridging.

Safety Precautions

Personal protective equipment (PPE) is necessary during cutting and handling.

Avoid inhalation of dust fibers; use dust masks and ventilation.

Follow local regulations regarding disposal of cutting waste.

Applications of Rockwool Wall Panels

Industrial Buildings: Factories, warehouses requiring fire safety and thermal control.

Commercial Buildings: Shopping malls, offices needing acoustic and energy efficiency.

Cold Storage: Panels with vapor barriers for refrigeration rooms.

Public Infrastructure: Schools, hospitals where fire resistance and hygiene are critical.

Residential Complexes: External cladding for thermal insulation and fire protection.

Frequently Asked Questions (FAQs)

Q1: How fire-resistant are rockwool wall panels?

A: Rockwool cores are classified A1 non-combustible, offering superior fire protection compared to many alternative insulation materials.

Q2: Are rockwool panels suitable for humid environments?

A: Yes, with proper facings and installation, they exhibit low water absorption and resist mold growth.

Q3: Can rockwool wall panels improve acoustic insulation?

A: Yes, their fibrous core effectively dampens sound, achieving sound reduction ratings up to 50 dB.

Q4: What is the expected lifespan of these panels?

A: With appropriate maintenance, rockwool wall panels can last 30+ years, retaining insulation and fire properties.

Q5: Are these panels environmentally friendly?

A: Rockwool is made from abundant natural materials and recycled slag, is recyclable itself, and contributes to energy savings, supporting sustainable building certifications.