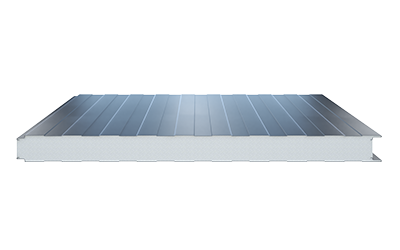

Insulated Roofing

Optimal Thermal Insulation: Maintains consistent temps in sensitive environments like refrigeration/freezer rooms.

Energy-Efficient & Cost-Effective: Minimizes energy loss for high efficiency and lower costs.

Moisture-Resistant Properties: Prevents mold/bacteria growth for hygienic conditions.

Durable & Strong: Ensures structural strength/stability in harsh conditions.

Easy Installation & Customizable Sizes: Enables flexible design/quick setup for cold storage, supermarkets, food plants.

Product Introduction

The quality of polyurethane cold room panels is influenced by multiple factors, primarily in the following three aspects:

1. Density: Typically 38-42kg/m³, with higher density improving insulation and compression strength.

2. Steel Thickness: Ranges from 0.4mm to 1.2mm, with thicker steel enhancing durability and load-bearing.

3. Load-bearing Capacity: Varies based on thickness, density, and material; 50mm panels support 1.5-2.5kN/m², while 200mm panels can exceed 5.5kN/m².

If your cold storage facility has specific load-bearing requirements (e.g., logistics, forklift operation), feel free to share details, and I can help optimize the solution!

Cold storage enclosure system

Our cold storage enclosure system is composed of insulated wall panels, roof, floor, doors, support plates, and base. Assembled with cam-lock systems, it ensures excellent insulation, moisture resistance, and cooling peformance. Ideal for food and pharma industries, this modular structure offers fast installation, durability, and efficient temperature control.

Thermal Parameters

| Types | Diagram | Density kg/m3 | Nominal Thermal Conductivity λ [W/(m·K)] | Thickness mm | Thermal Resistance R m2 ·k/W | Thermal Conductivity [W/(m2 ·K)] |

| PUR/PIR Sandwich Panel |  | 38-43k | 0.024 | 50 | 2.23 | 0.45 |

| 75 | 3.28 | 0.31 | ||||

| 100 | 4.32 | 0.23 | ||||

| 150 | 6.4 | 0.16 | ||||

| 200 | 8.42 | 0.12 | ||||

| 250 | 11.02 | 0.09 | ||||

| Note: The thermal conductivity is suitable for most projects but not for regions with hot summers and warm winters. | ||||||

Technical Parameters

| Sheet Specification | Width | 450-1120mm |

| Thickness | 30~250mm | |

| Length | Transportation Limitations | |

| Panel Specification | Material | Colored Coated Steel Plate、Galvalume Steel Sheet 、Stainless Steel Plate |

| Thickness | 0.4 ~ 0.8mm | |

| Coating | PE 、HDP、SMP、PVDF | |

| PIR | Fire Rating | B1 GR (Oxygen Index ≥ 30%) |

| Closed Cell Rate | ≥ 97% | |

| Water Absorption Rate | ≤ 3% | |

| Thermal Conductivity | 0.019-0.024 | |

| Heat Resistance Range | -196℃ +160℃ | |

| Compressive Strength | ≥ 120kpa |

Cold Store Panel Customizations

We offer customized panel surface options to meet your specific needs. You can choose from various textures such as corrugated, orange peel, and more, ensuring both functional performance and aesthetic appeal for your cold storage project.