Rockwool Acoustic Panels

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

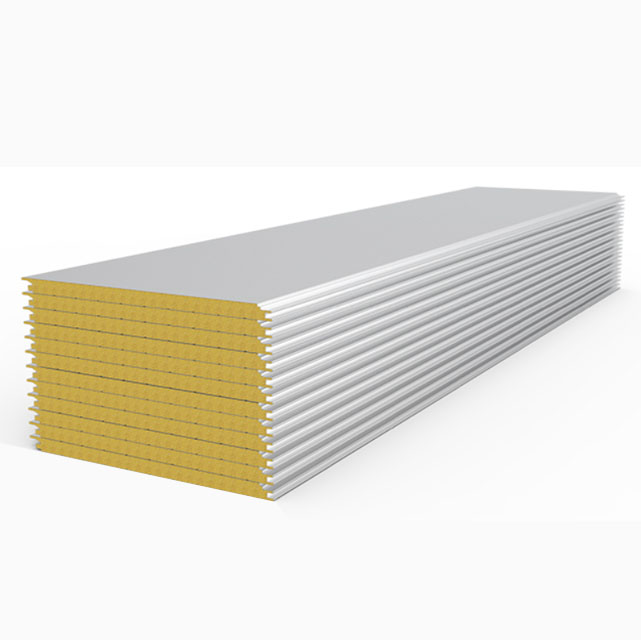

Rockwool Acoustic Panels combine functionality and safety, featuring dense rockwool fibers for excellent sound absorption, reducing noise in offices, hospitals, and more. With Class A fire-resistant cores, they meet strict safety standards. The material offers thermal insulation to stabilize indoor temps and cut energy use. Antibacterial coatings ensure hygiene in high-demand spaces. Lightweight yet durable, they’re easy to install and eco-friendly, made from natural basalt and recycled materials, ideal for versatile acoustic solutions.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Application Areas

Industrial plants: used for walls and roofs, providing insulation, fire protection, and sound insulation.

Warehouses: suitable for the walls and roofs of large warehouses to improve insulation effects.

Cold storage: used for cold storage walls, with excellent insulation performance.

Public buildings: such as gymnasiums, exhibition halls, etc., to meet fire protection and sound insulation requirements.

Temporary buildings: such as temporary buildings on construction sites, quick installation and reusable.

Color Selection

Discover a diverse spectrum of steel sheet colors! From the subtle sophistication of ivory and beige to the lively appeal of emerald green and lime, and the striking allure of raspberry and hot pink—there’s a shade for every vision. With a wide array of standard and premium hues, effortlessly match your aesthetic goals or project requirements, ensuring your steel sheets make a lasting impression.

Project Cases

Sandwich panels are widely utilized across multiple industries. In industrial construction, they are applied in projects like Gold and Silver Valley Industrial Park, factory buildings, and Jidong Intelligent Manufacturing New City. For transportation, they feature in Qingzhou High - Speed Railway Station. In cold storage, the International Fresh Cold Chain Park relies on them, while in healthcare, Hailier Pharmaceutical and Boxing People's Hospital benefit from their durability, energy efficiency, and hygienic properties.

Our Factory

Inside the factory, the smooth coordination of multiple production lines and the strategic arrangement of parts and components workshops facilitate fast material flow. This setup significantly reduces logistics costs during production and eliminates expenses from unnecessary loading and unloading processes.

Production Workshop

Our production workshop stands as a modern manufacturing hub, featuring a spacious layout equipped with advanced machinery and automated lines. Workspaces are meticulously organized for optimal efficiency, housing precision-operating equipment such as rolling and cutting machines. With safety and quality control as core priorities, the workshop maintains a clean, secure environment, exemplifying our capability to deliver high-quality products consistently.

Service

We stand by you at every stage of the purchasing journey. From the moment you choose our products to long after purchase, our comprehensive services—including on-site installation, professional consultation, long-term warranty, and prompt replacement—ensure a seamless, worry-free experience tailored to your needs.

Global Presence

Leveraging the developmental trends of the era, the company actively expands into the global market. With a presence in numerous countries worldwide and a broad business portfolio, it establishes a strategic cornerstone for sustained growth.

Certificates

Our company holds robust certifications underscoring quality and safety commitments, including the CE mark for EU compliance, ISO 9001 for quality management, SGS testing and approval for product reliability, and FM certification meeting strict risk-prevention standards, collectively demonstrating our industry credibility and leadership.

Transportation