Four-jointed Iindustrial Curtain Wall Panel

Variety of panel joint sizes: A wide variety of panel joint dimensions are available.

Rich coating options: The baked enamel coating offers a rich range of colors and high colorfastness.

Strong and durable: The core material has high strength, ensuring overall durability and reliability.

Bulk density parameters: Available in three specifications: 42, 120, and 64 kg/m².

Product Introduction

Combining superior performance with an exquisite appearance: As a material suitable for building exterior walls, it boasts excellent thermal insulation and fire resistance, and can be made of color-coated steel, aluminum, or stainless steel as needed. It is also a Class A energy-saving and fire-resistant material, effectively helping to reduce fire damage to buildings. In terms of protection, it can reduce noise by 30dB, and with water-repellent materials and a design that guides airtightness between panels, it offers excellent water and air tightness. Aesthetically, it features a screw-concealed joint design, high panel flatness, diverse panel joint sizes, and a rich and long-lasting painted coating, combining both aesthetics and texture. In terms of durability, the pure rock wool core material has high strength, with densities covering 42kg/m³, 120kg/m³, and 64kg/m³, ensuring a stable and reliable material sufficient to support the long-term use needs of buildings.

Production Workshop

Based in a state-of-the-art metal fabrication facility, the company boasts a seamlessly integrated suite of advanced manufacturing equipment. Its production ecosystem covers automated production lines, industrial robots, and precision tooling, overseeing the entire manufacturing process—from raw coil processing to the final forming of finished components. The synergy between large-scale CNC machining centers and intelligent logistics systems ensures highly efficient, precision-driven production that exemplifies cutting-edge manufacturing capabilities. This robust infrastructure provides reliable support for high-volume, premium-quality production of a wide range of metal parts, including specialized profiles such as tongue and groove plates.

Color Coated Steel Sheet Selection

Our color-coated steel sheets boast a sophisticated multi-layered structure: high-quality cold-rolled steel (base), plus metal plating, chemical conversion layer, high-performance primer and premium topcoat—working in tandem for exceptional quality. We offer coating structure options (2/1, 2/1M, 2/2) to fit diverse scenario needs (corrosion resistance, scratch resistance, processability). With strong coating adhesion and long-lasting color, they boost building durability, safety and facade aesthetics, making them ideal for high-quality metal cladding and exteriors.

Core Material Selection

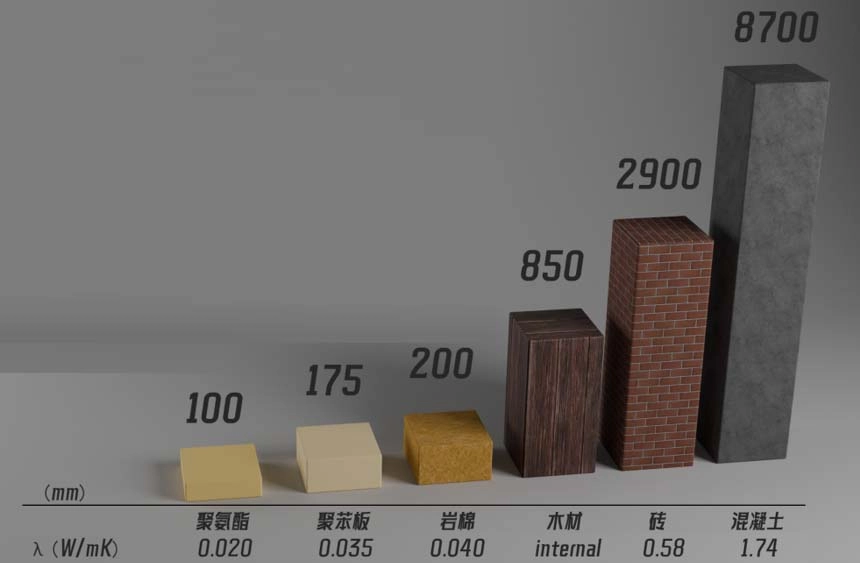

PU/PIR

Polyurethane offers exceptional insulation—50-100% thinner layers vs. other materials, thermal conductivity as low as 0.020 W/mK. Surpassing masonry by 29x and ordinary concrete by 87x, 100mm thickness delivers superior heat retention (outperforming wood/brick/concrete), boosting building insulation efficiency.

ROCK

We conduct strict waterproof tests on products per GB/T 10299: 1L/min continuous spraying for 1 hour. Short-term partial immersion water absorption ≤1kg/m²; long-term ≤3kg/m².

Product Cases

Our products undergo strict waterproof testing to ensure excellent moisture resistance. With robust structural design and premium materials, they boast outstanding durability, maintaining reliable performance for years in diverse building scenarios.