Rockwool PU Insulated Wall Slab

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

Rock wool fireproof sandwich panels crafted from high strength materials stand out as outstanding building materials. Their remarkable features include excellent fireproof heat - insulating and sound - insulating capabilities. The Class A non - combustible rock wool core within these panels offers an impressively high fire resistance limit. These panels find wide applications in various settings such as industrial plants civil buildings public facilities and clean workshops. They are lightweight yet robust facilitating easy installation. Moreover they are environmentally friendly and highly durable. In summary due to their fireproof energy - saving and heat - preservation qualities rock wool fireproof sandwich panels are the perfect choice for construction projects.

Product Specifications

Rock wool PU Sandwich Panel | |

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

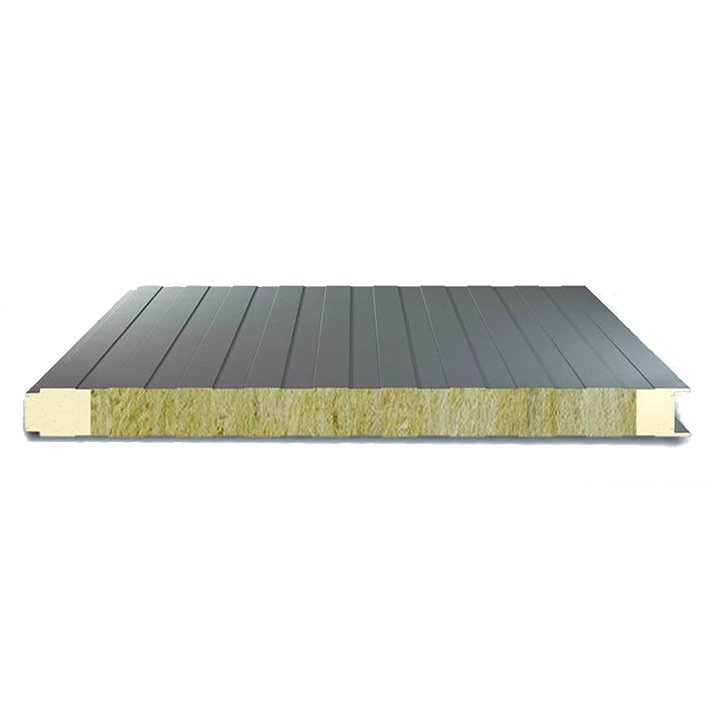

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Application Areas

Industrial plants: used for walls and roofs, providing insulation, fire protection, and sound insulation.

Warehouses: suitable for the walls and roofs of large warehouses to improve insulation effects.

Cold storage: used for cold storage walls, with excellent insulation performance.

Public buildings: such as gymnasiums, exhibition halls, etc., to meet fire protection and sound insulation requirements.

Temporary buildings: such as temporary buildings on construction sites, quick installation and reusable.

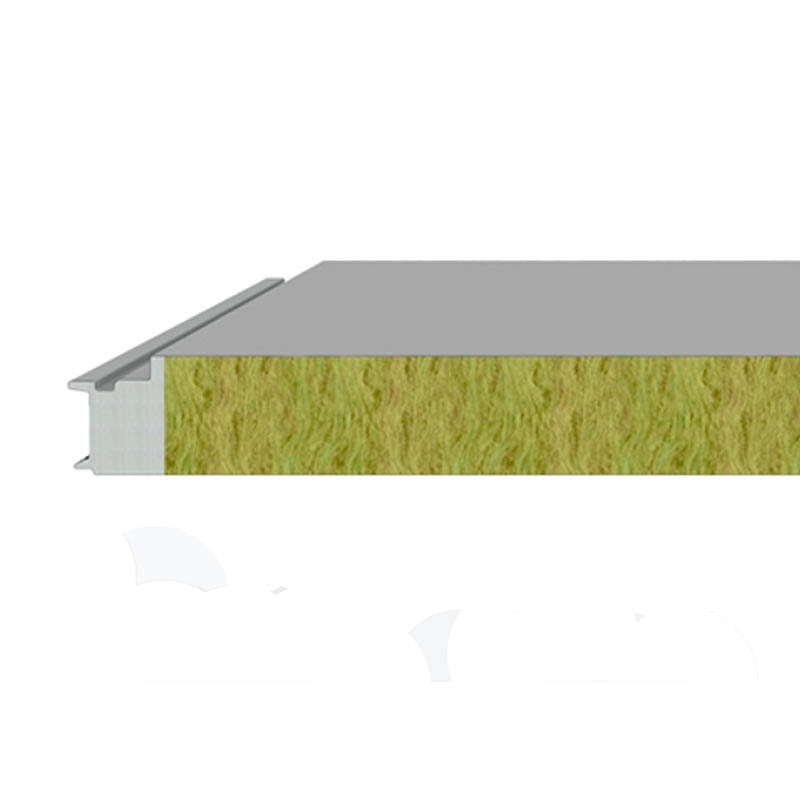

Lap Way

There exist numerous methods for overlapping sandwich panels. These include seamless overlapping with concealed nails, 20 millimeter seam overlapping with concealed nails, 10 millimeter seam overlapping with concealed nails, and tongue and groove overlapping.

As modern construction increasingly prioritizes energy efficiency, fire resistance, and acoustic performance, Rockwool PU insulated wall slabs have emerged as a premier solution in commercial, industrial, and residential buildings. These composite panels combine the thermal insulation of polyurethane (PU) with the fireproof and soundproof benefits of rockwool, creating a multifunctional wall cladding material. This article provides a detailed analysis of the materials, engineering properties, regulatory considerations, benefits, limitations, and applications of Rockwool PU insulated wall slabs.

What Is a Rockwool PU Insulated Wall Slab?

A Rockwool PU insulated wall slab is a sandwich panel composed of:

Exterior skins: Often made of galvanized or pre-painted steel.

Inner core: Comprising dual-layer insulation—polyurethane foam (PU) for thermal resistance and rockwool (mineral wool) for fireproofing and sound insulation.

These layers are bonded under pressure to ensure durability, rigidity, and consistent performance across temperature cycles.

Key Benefits

1. Thermal Insulation

PU Foam has a low thermal conductivity of ~0.022–0.028 W/m·K.

Provides compliance with ASHRAE 90.1 and EN ISO 6946 insulation standards.

Reduces energy consumption in HVAC systems by up to 30–50% in well-sealed buildings.

2. Fire Resistance

Rockwool is non-combustible and rated Class A1 under EN 13501-1.

Can resist temperatures up to 1000°C, making it suitable for high-risk industrial environments.

Delays flame spread in case of fire, meeting NFPA 285 fire propagation test requirements.

3. Acoustic Performance

Rockwool density (~100–150 kg/m³) effectively absorbs sound waves.

Reduces noise transmission by up to 50–60 dB, depending on thickness.

Ideal for industrial zones, airports, mechanical rooms, and commercial buildings.

4. Moisture and Chemical Resistance

PU foam is closed-cell, offering water absorption rates below 2%.

Outer metal skins can be coated with anti-corrosive finishes (e.g., PVDF or SMP).

Compliant with ASTM C518 and ISO 9229 for insulation under variable humidity.

Applications

Cleanrooms and cold storage warehouses

High-rise building façades

Power stations and industrial plants

Noise barrier walls near highways or factories

Data centers and server rooms

Engineering and Structural Considerations

Load Bearing

Typical compressive strength: 150–250 kPa (PU) and 80–160 kPa (rockwool).

Panel span varies based on thickness (50–150 mm) and support structure.

Panel Sizes

Standard length: Up to 12 meters

Thickness options: 50mm, 75mm, 100mm, 150mm

Width: Generally 950mm or 1000mm effective coverage

Joint System

Tongue-and-groove or concealed fixing systems ensure airtight sealing and aesthetic appeal.

Compliance with Standards and Codes

| Standard | Relevance |

|---|---|

| EN 14509 | Structural requirements for sandwich panels |

| ASTM C1363 | Thermal performance testing |

| EN ISO 1182 | Reaction to fire testing |

| ISO 140-3 | Sound insulation in building elements |

Common FAQs

Q1: Is Rockwool PU panel safe for residential use?

A: Yes. It combines the thermal comfort of PU with the non-toxicity and fire safety of mineral wool, making it safe for residential walls and façades.

Q2: Can it be used in cold climates?

A: Absolutely. PU’s high R-value ensures performance in sub-zero temperatures, while the rockwool layer adds additional thermal buffering and stability.

Q3: What’s the expected lifespan of such panels?

A: With proper installation and surface treatment, the panels can last 25–40 years, depending on environmental exposure.

Q4: Is installation complicated?

A: No. Panels are prefabricated, lightweight, and can be installed using concealed fasteners, making the process efficient and clean.

Installation Guidelines

Use a moisture barrier and ventilated cavity in humid zones.

Seal all joints with approved fire- and weather-resistant sealants.

Store panels horizontally in dry conditions prior to installation.

Follow all occupational safety standards (OSHA, ISO 45001) during handling and cutting.

Limitations to Consider

PU foam is combustible without rockwool encapsulation.

May not be suitable for curved or highly irregular surfaces.

Higher initial cost than basic EPS or PU-only panels—but justified by long-term performance.

Conclusion

The Rockwool PU insulated wall slab offers a comprehensive solution for thermal insulation, fire safety, acoustic control, and structural integrity. It meets international engineering and environmental standards, making it ideal for sustainable and high-performance construction projects.