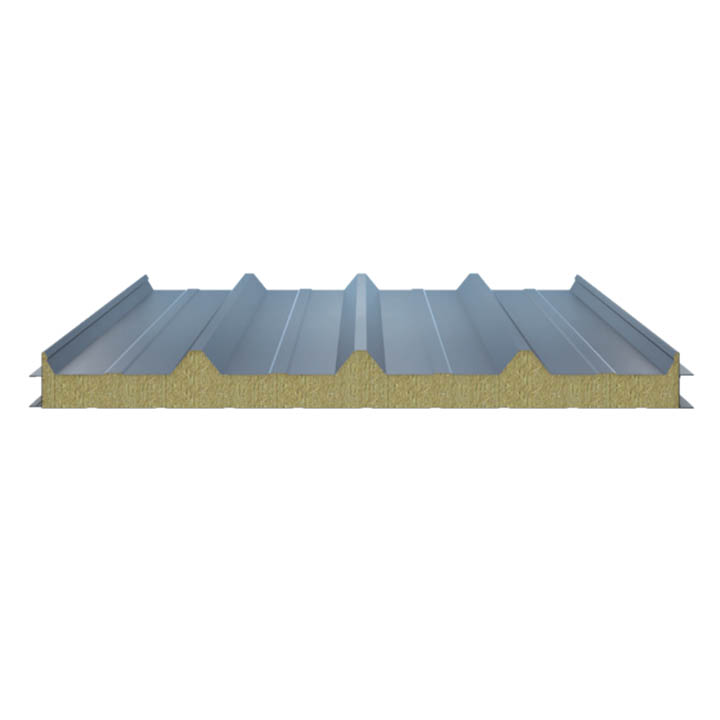

Roof Rock Wool Sandwich Panel

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

Roof Rock Wool Sandwich Panels, crafted from high - strength panels, are outstanding roofing materials. Their Class A non - combustible rock wool core endows them with remarkable fireproof, heat - insulating, and sound - insulating properties, along with a high fire resistance limit, ensuring top - notch fire safety for rooftops. Lightweight yet strong enough to withstand various weather conditions, they reduce the load on the roof structure. They are an ideal fit for industrial plant roofs, civil building rooftops, public facility rooftops, and clean workshop rooftops. Installation is easy, and they are eco - friendly and durable, making them the perfect choice for rooftop fireproofing, energy - saving, and heat - preservation, and a popular option for modern roofing projects.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Application Areas

Industrial plants: used for walls and roofs, providing insulation, fire protection, and sound insulation.

Warehouses: suitable for the walls and roofs of large warehouses to improve insulation effects.

Cold storage: used for cold storage walls, with excellent insulation performance.

Public buildings: such as gymnasiums, exhibition halls, etc., to meet fire protection and sound insulation requirements.

Temporary buildings: such as temporary buildings on construction sites, quick installation and reusable.

Lap Way

There exist numerous methods for overlapping sandwich panels. These include seamless overlap with concealed nails, 20 - millimeter seam overlap with concealed nails, 10 - millimeter seam overlap with concealed nails, and tongue - and - groove overlap.

The roof rock wool sandwich panel is a high-performance building material widely adopted in industrial, commercial, and institutional construction projects. It offers exceptional thermal insulation, fire resistance, and acoustic performance, making it an ideal solution for modern roofing systems requiring safety, efficiency, and compliance with global construction standards.

This article provides an in-depth analysis of roof rock wool sandwich panels, including their composition, performance parameters, engineering principles, regulatory compliance, and installation guidelines.

What Is a Roof Rock Wool Sandwich Panel?

Definition:

A roof rock wool sandwich panel consists of a non-combustible rock wool core layered between two structural metal facings (typically pre-painted galvanized steel), forming a composite roofing system with excellent insulation and load-bearing capacity.

Key Benefits:

Fireproof and flame-retardant (Euroclass A1)

High compressive and flexural strength

Excellent sound absorption

Superior thermal resistance (λ ≤ 0.045 W/m·K)

Fast and modular installation

✅ Ideal Applications: Industrial plants, logistics centers, warehouses, cleanrooms, cold storage facilities, and airport terminals.

Panel Composition and Structure

| Component | Material/Property |

|---|---|

| Outer Facing | 0.4mm–0.7mm PPGI / Al-Zn coated steel |

| Core Material | High-density rock wool (100–150 kg/m³) |

| Inner Facing | Galvanized steel / aluminum / coated steel |

| Insulation Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

| Panel Width | Effective width: 1000mm / 1150mm |

| Joint Type | Overlap or concealed fastener joint (seam-locked) |

| Fire Rating | EN 13501-1 A2-s1,d0 or A1 |

Performance Parameters and Engineering Analysis

Thermal Conductivity and Insulation

Rock wool core offers thermal conductivity of λ ≤ 0.045 W/m·K

Achieves U-values compliant with IECC, ASHRAE 90.1, and EN ISO 6946

Reduces energy loss through roofs in climates ranging from -40°C to +70°C

Fire Safety Performance

| Standard | Rating |

|---|---|

| EN 13501-1 | Class A1 (non-combustible) |

| ASTM E84 | Flame Spread Index < 25 |

| FM Approvals 4880 | Available on request |

Sound Insulation

Sound absorption coefficient (αw): up to 1.00 (EN ISO 11654)

Suitable for noise-sensitive environments, such as near highways or machinery zones

Mechanical Strength

Bending resistance: ≥ 0.5 kN/m² for 100mm thick panels

Support span: Up to 3–4 meters depending on thickness and wind load

Wind uplift resistance: Designed per EN 14509 and ASCE 7

Installation Guidelines

Preparation:

Subframe should be made of purlins or rafters, aligned and leveled

Panels must be stored on-site with moisture protection

Installation Best Practices:

Use concealed fastener systems with EPDM gaskets for waterproofing

Maintain overlap of ≥100mm between panels for rain-tightness

Seal all joints with non-combustible mineral wool where required by code

Follow roof slope recommendations: typically ≥5% (3°) for drainage

Fastening System:

Self-tapping screws with thermal break washers

Fixing interval: ≤300mm along seams

Compliance with Global Construction Standards

| Standard | Relevance |

|---|---|

| EN 14509 | Self-supporting double-skin metal panels |

| FM Global 4880/4471 | Fire resistance and wind uplift |

| CE Marking (CPR) | Structural safety & fire performance |

| ISO 9001 / 14001 | Quality and environmental management |

| LEED / BREEAM | Contributes to green building certification |

Use Cases and Application Examples

Case Study 1 – Cold Storage Roofing:

Panel Type: 150mm roof rock wool panel

Result: Reduced thermal loss by 35%, passed EN fire safety audit

Case Study 2 – Logistics Center:

Panel Type: 100mm thickness

Performance: Wind load resistance of 2.5kN/m², acoustic attenuation of 27dB

Maintenance and Durability

Lifespan: 25–35 years with standard maintenance

Inspection: Annual checks on fasteners, joints, and coatings

Cleaning: Non-abrasive cleaners; avoid acid-based solutions

FAQs: Roof Rock Wool Sandwich Panels

Q1: Can these panels be used in high-humidity environments?

Yes. The panels resist moisture and condensation, especially when installed with vapor barriers.

Q2: Are they suitable for photovoltaic roofs?

Yes. Their structural integrity supports solar panel installations when properly reinforced.

Q3: Do they contribute to green building certification?

Yes. They offer thermal efficiency, fire safety, and recyclability—supporting LEED, WELL, and BREEAM points.

Q4: How are cut-outs for skylights or HVAC ducts handled?

Cutting is performed on-site using metal shears or circular saws with dust control and edge protection applied post-cutting.

Conclusion

Roof rock wool sandwich panels are a high-performance, regulation-compliant solution for safe, energy-efficient roofing. By combining non-combustible mineral cores with structural steel, they meet the stringent requirements of modern industrial and commercial construction. Whether for new builds or retrofits, these panels offer unmatched performance in insulation, fire safety, and acoustics.