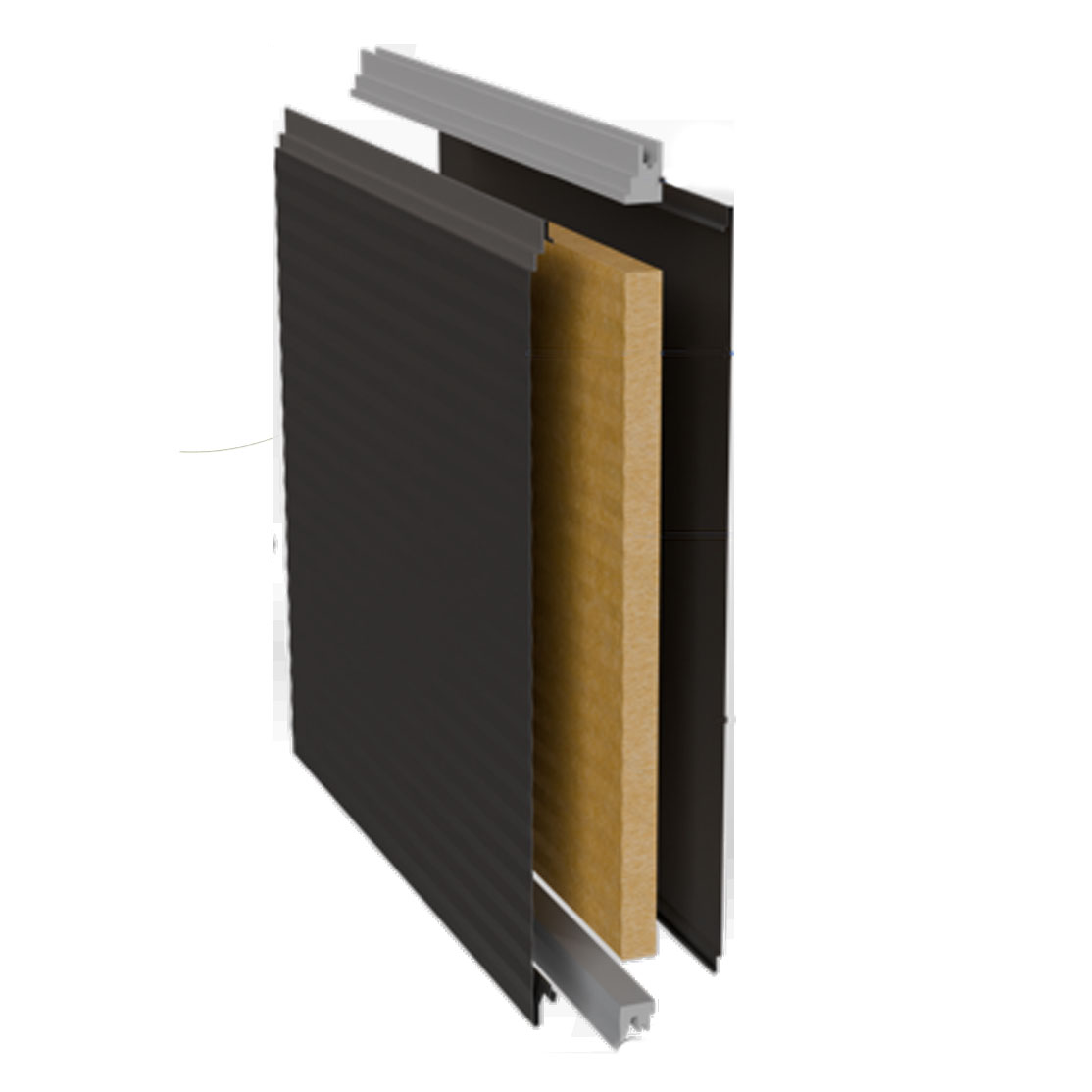

Hidden Nail Tongue Groove Sandwich Panels

Fire Rating:A/B class fire-resistant energy-saving panels comply with strict building fire safety requirements.

Fire Protection Effect:Shields buildings effectively against fire risks and reduces potential fire-related losses.

Sound Insulation:Cuts external noise interference by 30dB, delivering a peaceful indoor space.

Watertightness:Hydrophobic material property prevents moisture intrusion for reliable water resistance.

Product Introduction

The QuadFacade System offers a high-performance building envelope solution combining excellent fire safety, durability, and aesthetic flexibility. It features Class A1/B1 fire-rated materials per GB8624-2012, significantly reducing fire risks. The system provides effective sound insulation (up to 30dB reduction), along with reliable water and air tightness.

With concealed fasteners and uniform panel surfaces, it ensures a clean architectural appearance. Available in various seam profiles and durable painted finishes, it maintains long-lasting color consistency. The panels utilize high-density core materials (42kg/m³, 64kg/m³, 120kg/m³) for enhanced structural strength.

Characteristics

| Parameter | Description |

| Processing Technology | Outer Panel: 0.5-0.7mm / G350 Inner Panel: 0.4-0.6mm / G350 |

| Supply Dimensions | Width: 500-1200mm Thickness: 40-200mm Length: According to transport & installation |

| Surface Material | Color Coated Steel Sheet / Stainless Steel / Color Coated Aluminum Sheet |

| Core Material | PU+ROCK / PU+GLASS |

| Surface Pattern | Small Wave / Wide Rib / Pure Flat / Embossed / Printed |

| Fire Rating | Class A per 《GB8624-2012 Classification for Burning Behavior of Building Materials》 |

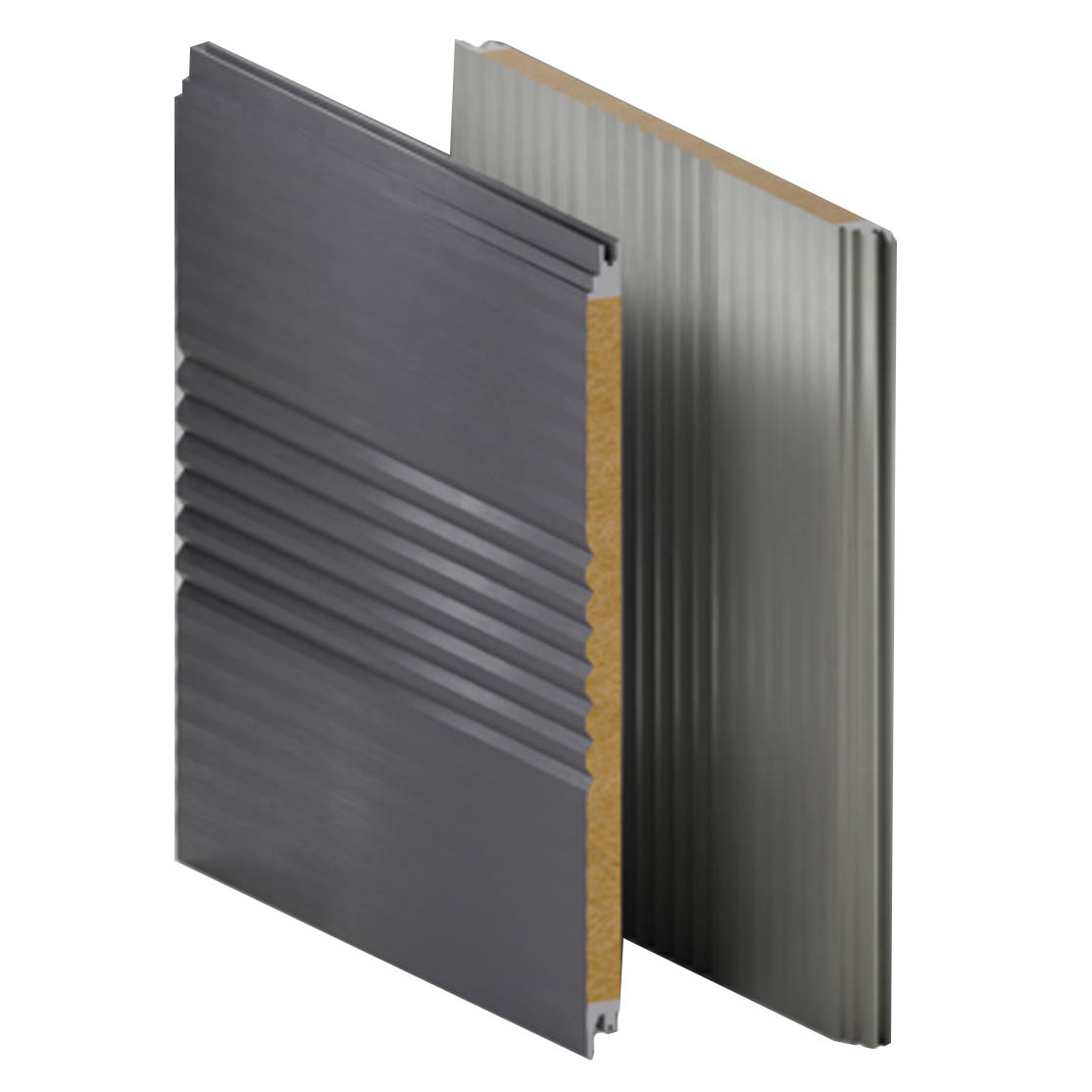

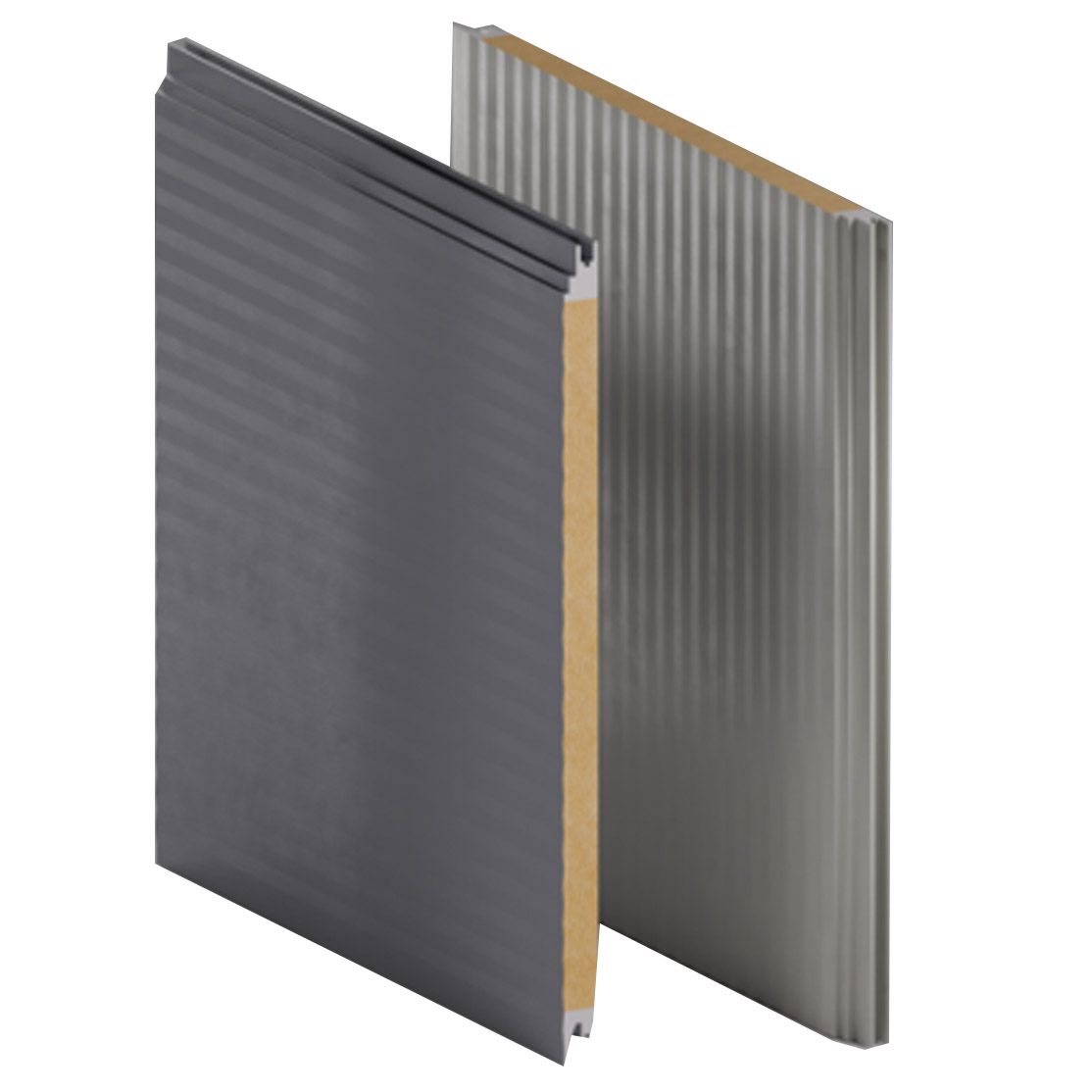

Plug Connector

HXY-FD-W-LHEB Series

Features a 20mm seam width design, providing a clean and modern architectural aesthetic while maintaining structural integrity.

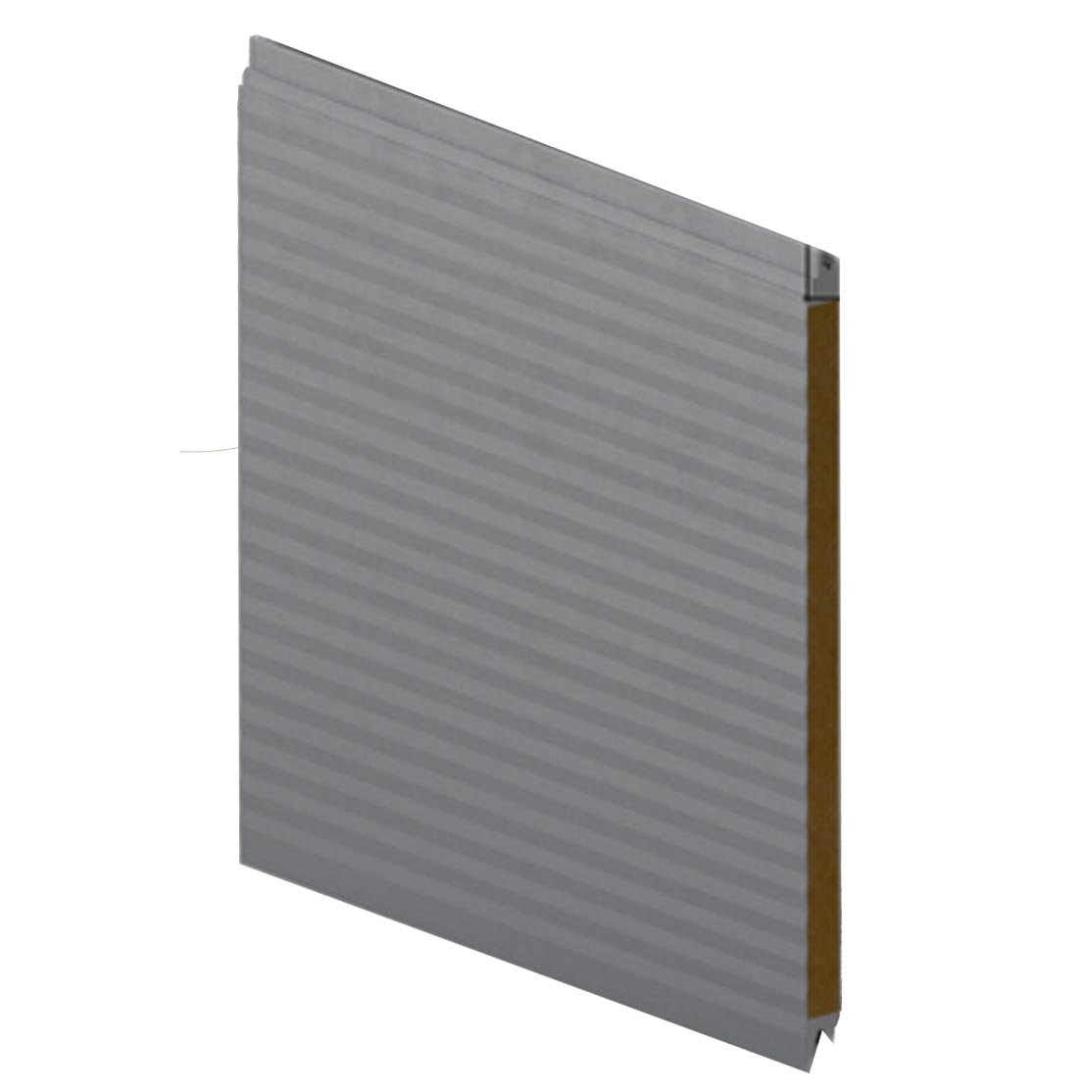

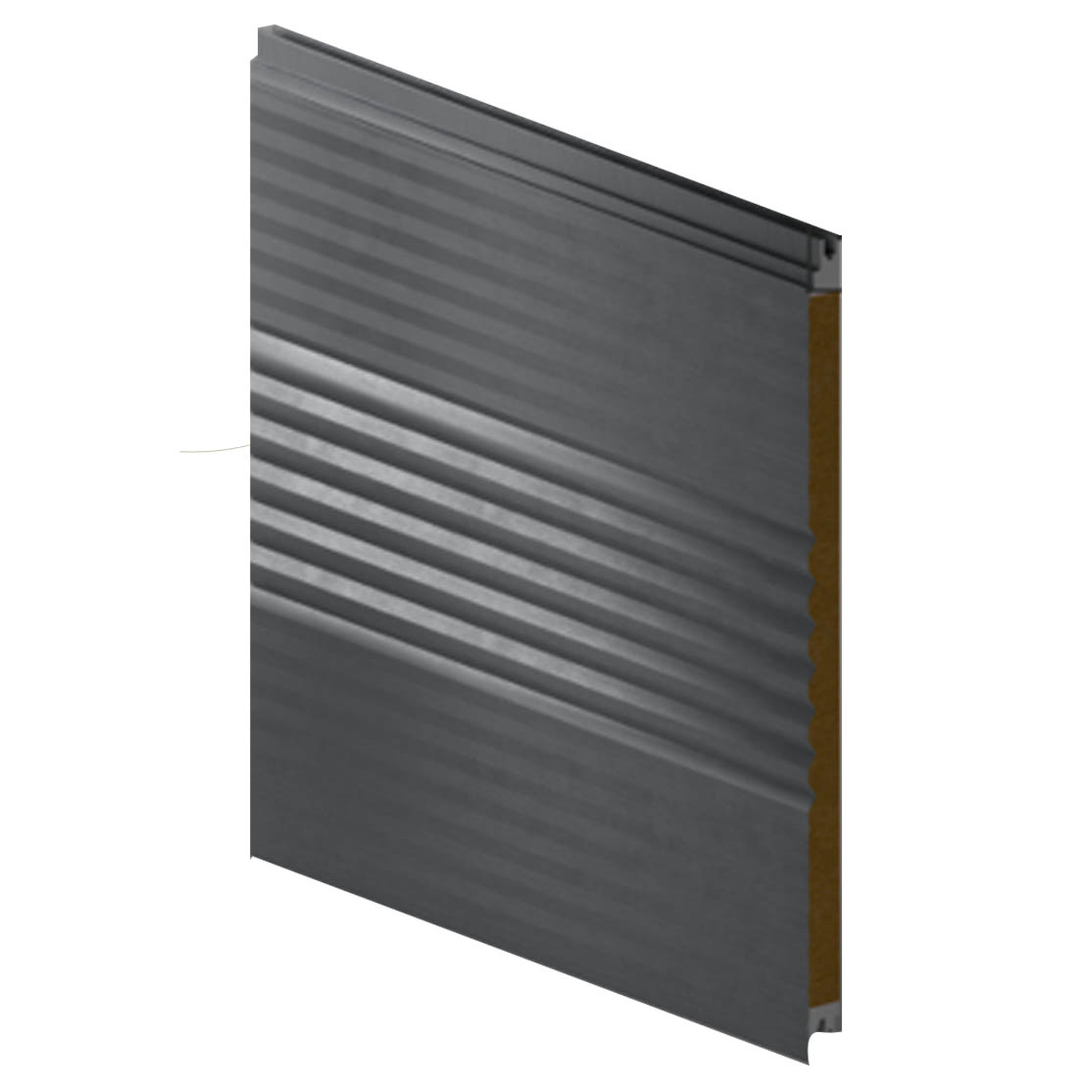

HXY-FD-W-SHEB Series

Offers flexible seam width options (10mm or 20mm), allowing for customized facade designs to meet different architectural style requirements.

Interlocking & Thermal Insulation Technology

The system incorporates precision interlocking joints with securely grooved connections, enabling accurate and efficient installation. Combined with high-performance insulation core materials, it ensures excellent thermal break performance and enhanced energy efficien

Production Workshop

The company utilizes a modern metal products factory workshop with advanced and well-organized equipment. It is equipped with multiple automated production lines, intelligent robotic arms, and precision machining equipment, covering the entire process from raw material coil processing to sheet metal processing and component forming. From large-scale CNC machining equipment to intelligent conveying systems, various advanced equipment operate in tandem, ensuring both high efficiency and precision in production. This demonstrates the company's modern production capabilities in the field of metal products manufacturing, and can meet the large-scale, high-quality production needs of various metal components, such as tongue and groove plates.