Metal Tongue And Groove Panel

Airtightness:Airtight-oriented joint design between panels enhances building airtight performance.

Facade Details:Hidden screw nodes and high panel flatness ensure neat, attractive facade appearance.

Color & Coating:Rich long-lasting baking paint coatings and diverse joints boost visual versatility.

Durability:Three core densities (42/64/120kg/m³) offer high strength and long-term stability.

Product Introduction

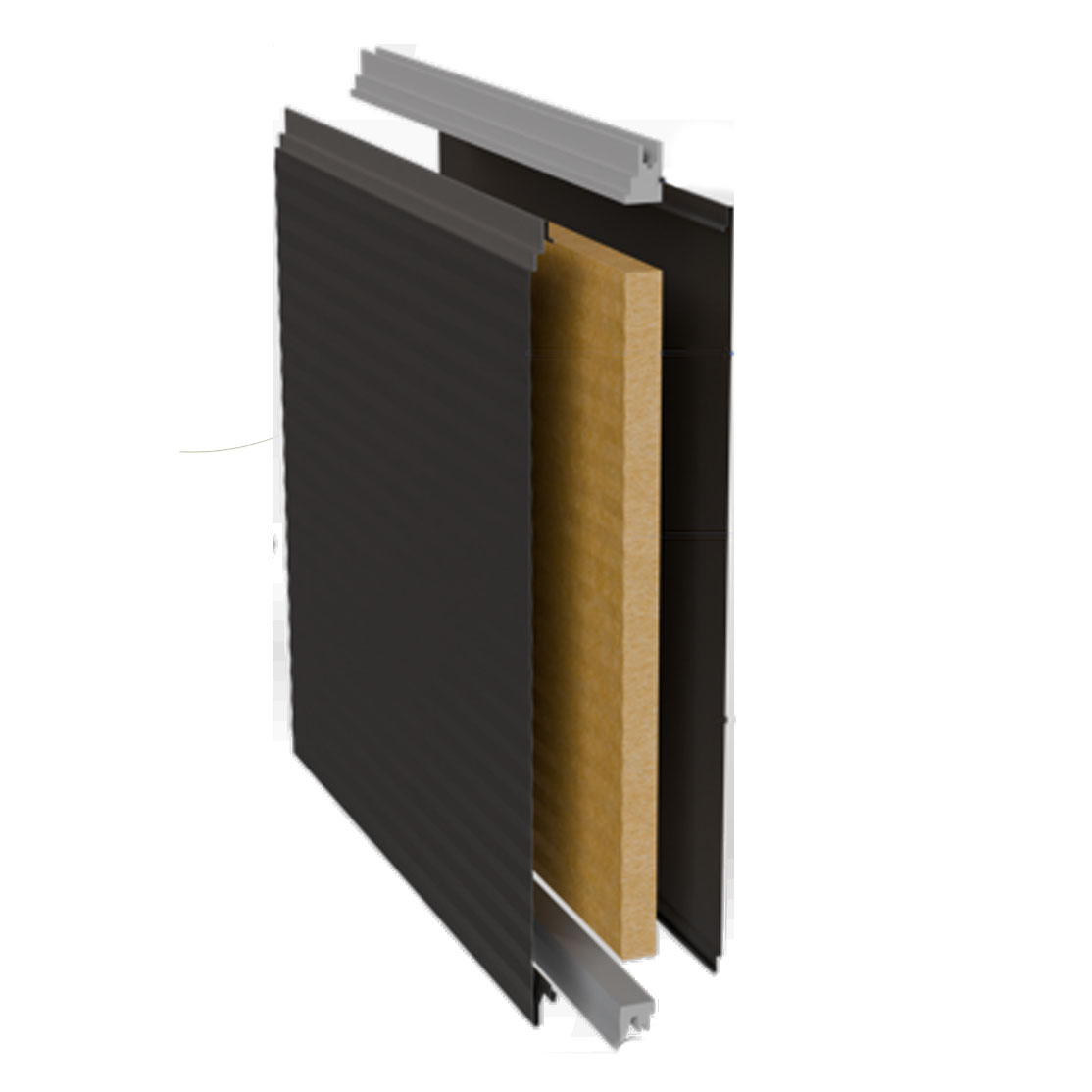

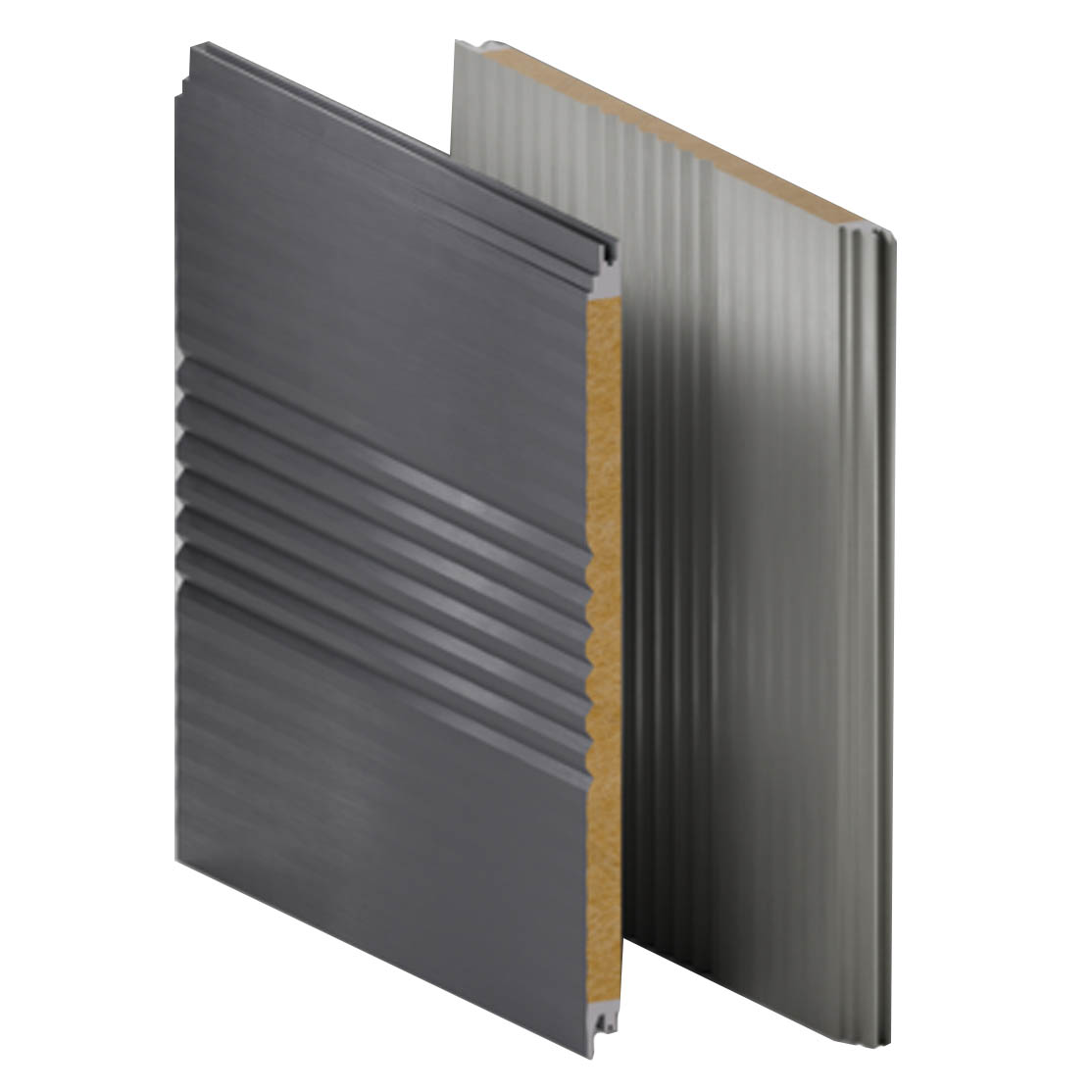

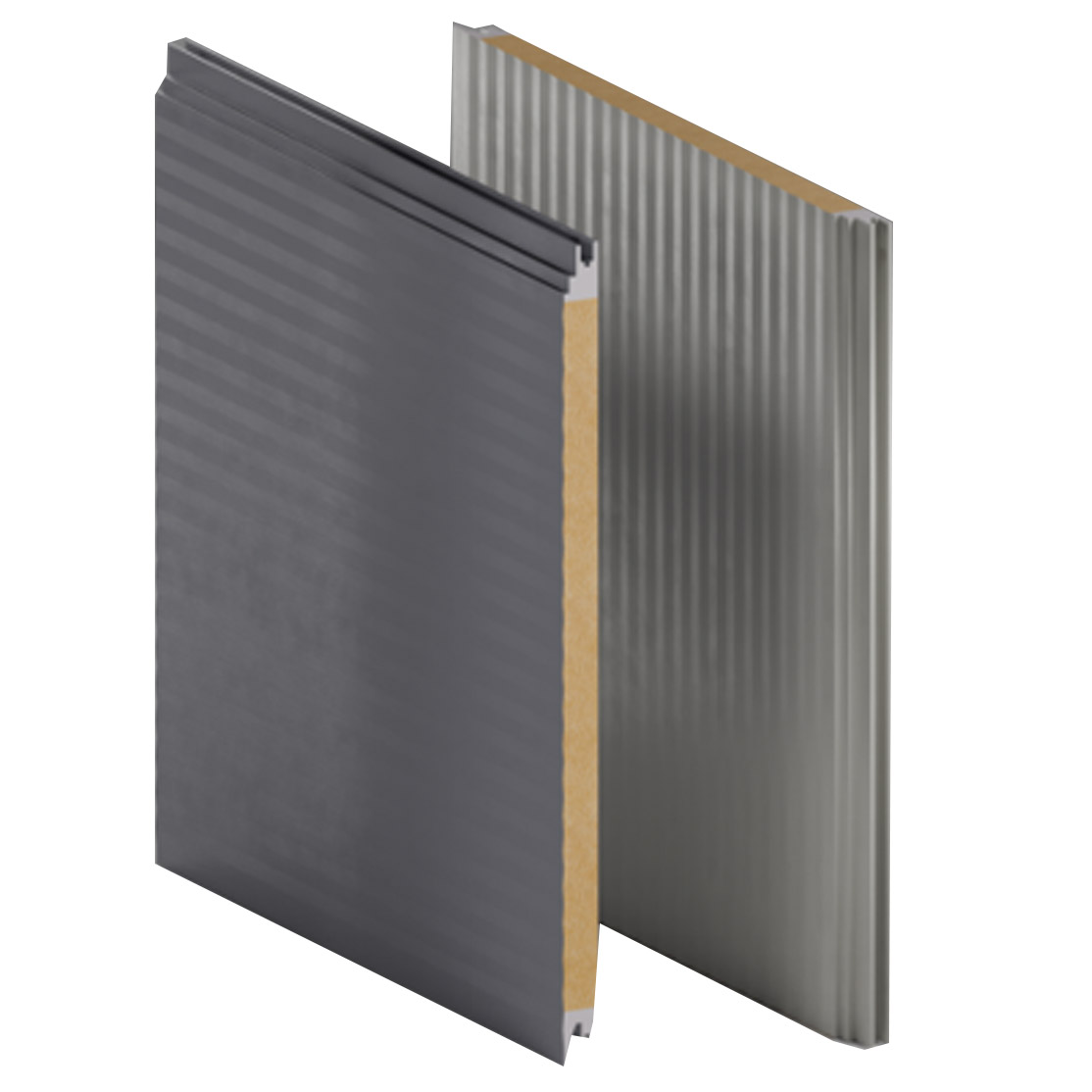

The product features a concealed fastener design and a smooth, uniform panel surface, creating a clean and sleek architectural appearance. It offers a variety of seam styles and a durable coating that maintains color stability over the long term. The core material is made of high-density material, available in three specifications: 42kg/m³, 64kg/m³, and 120kg/m³, effectively enhancing the structural strength of the panels.

Characteristics

| Parameter | Description |

| Processing Technology | Outer Panel: 0.5-0.7mm / G350 Inner Panel: 0.4-0.6mm / G350 |

| Supply Dimensions | Width: 500-1200mm Thickness: 40-200mm Length: According to transport & installation |

| Surface Material | Color Coated Steel Sheet / Stainless Steel / Color Coated Aluminum Sheet |

| Core Material | PU+ROCK / PU+GLASS |

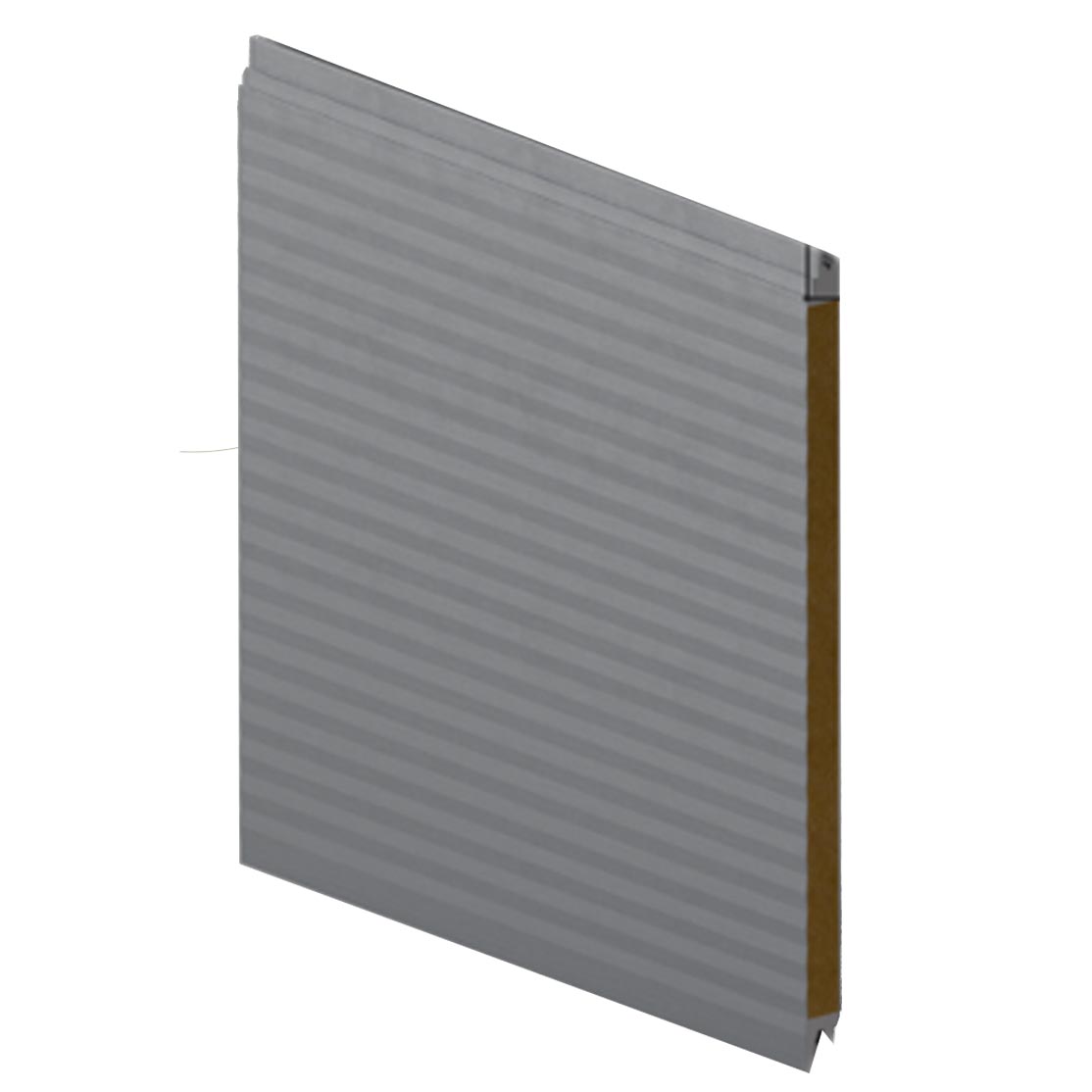

| Surface Pattern | Small Wave / Wide Rib / Pure Flat / Embossed / Printed |

| Fire Rating | Class A per 《GB8624-2012 Classification for Burning Behavior of Building Materials》 |

Core Material Selection

PU/PIR

Polyurethane possesses excellent thermal insulation properties, requiring 50%-100% less insulation layer thickness compared to other insulation materials. Its insulation effect is particularly outstanding, being 29 times that of masonry and 87 times that of ordinary concrete, with a thermal conductivity of only 0.020 W/mK. A thickness of only 100mm is sufficient to achieve superior insulation performance, far exceeding that of materials such as wood, brick, and concrete, thus effectively improving the thermal insulation performance of buildings.

ROCK

Our company conducts rigorous water-repellent performance tests on the product. Based on the GB/T 10299 standard, the product is sprayed continuously for 1 hour at a stable water flow rate of 1L/min. The results show that short-term (partially soaked) water absorption is ≤1kg/m², and long-term (partially soaked) water absorption is ≤3kg/m².

Simultaneously, the product exhibits excellent moisture absorption and water-repellent properties, with a moisture absorption rate ≤1% and a water repellency rate ≥99%. In actual use, it demonstrates a clear "lotus leaf effect," allowing water droplets to roll off its surface smoothly, effectively resisting moisture intrusion and ensuring stable performance in humid environments, fully showcasing its reliable quality in waterproofing and moisture-proofing.

Production Workshop

The company boasts a modern metal products manufacturing workshop featuring state-of-the-art equipment and a streamlined layout. It houses multiple automated production lines, intelligent robotic arms, and precision machining tools, encompassing the full production workflow—from raw material coil processing and sheet metal forming to component stamping.

Large-scale CNC machining equipment, intelligent conveying systems, and other cutting-edge facilities operate in synergy to guarantee both production efficiency and machining accuracy. This fully showcases the company's modern manufacturing capabilities in the metal products sector, empowering it to fulfill the requirements for large-scale, high-quality production of various metal components—including tenon and groove plates.