Ceramic Thin Plate

Ceramic thin plates provide a lightweight, high-strength, and durable surface for architectural and industrial applications. With thicknesses ranging from 3–6 mm, they reduce structural load while offering superior flexural strength (≥30 MPa), fire resistance (Class A1), and low water absorption (<0.5%). Their chemical and UV resistance ensures longevity, while the wide range of finishes enables both functional and decorative applications. Compliant with EN 14411, ISO 10545, and ASTM standards, these plates are ideal for facades, wall cladding, and partitions. Quick installation, low maintenance, and long-term stability make ceramic thin plates a cost-effective, high-performance solution in modern construction.

Ceramic thin plates are high-performance materials widely applied in architectural facades, interior wall cladding, and industrial panels. Combining aesthetic appeal, mechanical strength, and low weight, these plates meet modern construction and design requirements while adhering to international standards.

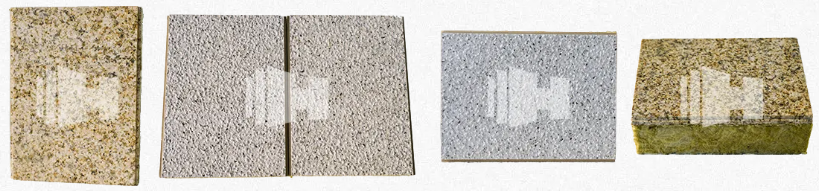

Material Composition and Properties

Base Material: High-density porcelain or ceramic composites.

Thickness: Typically 3–6 mm, reducing weight while maintaining structural integrity.

Surface Treatment: Glazed or matte finishes improve resistance to abrasion, UV, and chemical corrosion.

Mechanical Properties: Flexural strength ≥ 30 MPa, water absorption ≤ 0.5%, thermal expansion coefficient ≈ 7×10⁻⁶/K.

Engineering Principles

Structural Performance:

Designed according to EN 14411 and ISO 10545 standards.

Capable of withstanding bending stresses when properly supported.

Thermal and Moisture Resistance:

Low thermal expansion ensures stability in indoor and outdoor environments.

Water absorption <0.5% prevents frost damage in exterior applications.

Fire and Safety Compliance:

Non-combustible, Class A1 fire rating per EN 13501.

Ideal for fire-resistant partitions and cladding.

Installation Guidelines

Use adhesive mortars suitable for thin ceramic panels.

Ensure flat, rigid substrates to prevent bending or cracking.

Maintain 2–3 mm grout spacing for thermal expansion.

Avoid over-tight mechanical fixings that may stress the plate.

Applications

High-end architectural facades.

Interior wall cladding and partition panels.

Industrial panels in chemical and moisture-prone environments.

Decorative flooring in low-traffic areas.

Maintenance

Clean with mild detergents; avoid acidic or abrasive chemicals.

Inspect joints periodically for wear or sealant degradation.

Replace cracked panels immediately to prevent structural and aesthetic damage.

Advantages

Ultra-thin, lightweight, reducing load on structures.

High flexural strength and durability.

Excellent fire, moisture, and UV resistance.

Low water absorption and chemical resistance prolong lifespan.

Compliant with EN, ISO, and ASTM standards for construction safety and performance.

Frequently Asked Questions (FAQ)

Q1: Can ceramic thin plates be used outdoors?

Yes, low water absorption and UV-resistant surface make them suitable for facades.

Q2: What thickness is recommended for wall cladding?

3–5 mm is typical; thicker options can be used for impact resistance.

Q3: How are thin plates installed on uneven surfaces?

Substrate leveling with mortar or cement boards is required to prevent stress fractures.

Q4: What is the expected service life?

With proper installation and maintenance, 25–30 years is achievable.

Professional Conclusion and Call-to-Action

Ceramic thin plates deliver lightweight, durable, and aesthetically versatile solutions for modern architecture and industrial applications. Their compliance with EN 14411, ISO 10545, and ASTM standards ensures fire safety, structural stability, and long-term performance.

Contact our technical team today to select the optimal ceramic thin plate solution for your project’s requirements.