PU and Rockwool Panel

Sound insulation: Porous structure absorbs sound, reduces noise for soundproof needs

Corrosion resistance: Acid-alkali resistant, stable property ensures long service life

High compressive strength: Tight structure, good compression resistance for load-bearing use

Product Introduction

Polyurethane-edge-sealed rock wool panels come with a wealth of outstanding advantages. Fireproof performance stands out prominently: the inherently non-combustible rock wool core paired with professionally processed polyurethane delivers excellent fire resistance rating, forming a solid fire protection barrier. It also boasts remarkable thermal insulation; the synergistic effect of polyurethane and rock wool efficiently curbs heat loss and locks in temperature stability. Its airtight sealing performance is superior, effectively blocking air, vapor and dust intrusion to protect the core material and greatly prolong the panels' service lifespan. Moreover, the polyurethane edge-sealing process reinforces the overall structural rigidity of the panels, minimizing the risk of damage during transportation and on-site application. In addition, the panels feature a sleek and smooth surface finish, achieving a perfect integration of high functionality and elegant visual appeal.

Product Specifications

Rock wool Sandwich Panel | |

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Lap Way

Composite sandwich panels support diverse lapping connection methods for on-site installation. Seamless lapping paired with concealed fasteners delivers an ultra-smooth, blemish-free surface with no visible joints at all. For 20mm and 10mm lap joints that also adopt hidden fastener design, the visibility of panel connecting seams varies distinctly to meet different project needs. Furthermore, the tongue-and-groove lapping method gains high popularity among clients, as it ensures tight and secure engagement between adjacent panels for enhanced structural stability.

Core Material Selection

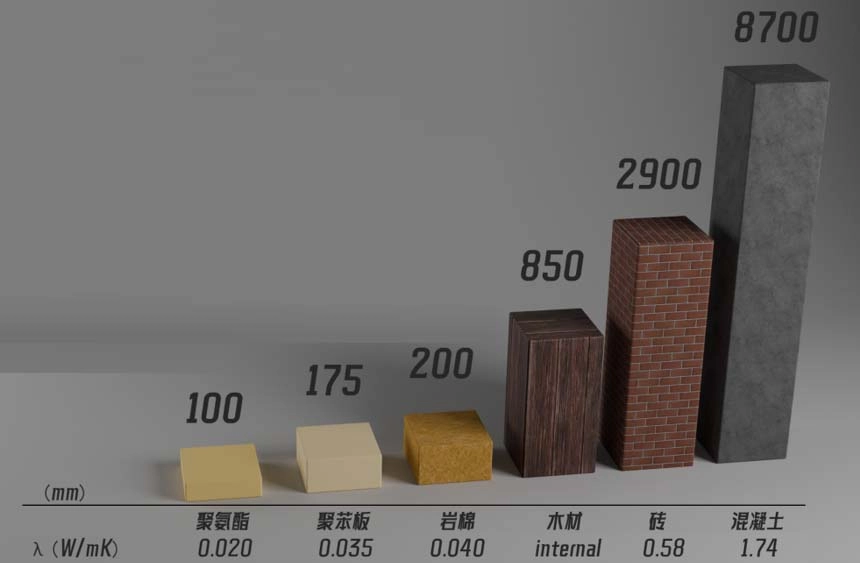

PU/PIR

Polyurethane features outstanding thermal insulation performance, requiring insulation layers 50% to 100% thinner than those of conventional thermal materials. Its heat retention capacity is exceptionally remarkable: it outperforms masonry by 29 times and regular concrete by 87 times, with a thermal conductivity as low as 0.020 W/mK. A mere 100mm-thick polyurethane layer suffices to achieve superior heat preservation, far surpassing such materials as wood, brick and concrete by a huge margin, thus effectively boosting the overall thermal performance of buildings.

ROCK

Our company conducts rigorous waterproof performance testing on this product to ensure reliable quality. In line with the national standard GB/T 10299, the product undergoes continuous water spraying for 1 hour with a stable flow rate of 1 liter per minute. Test findings show that its water absorption rate is no more than 1kg/m² under short-term partial immersion, and the index remains ≤3kg/m² for long-term partial immersion scenarios.

Meanwhile, this product excels in moisture absorption control and water repellency, with a maximum moisture absorption rate of 1% and a minimum water repellency rate of 99%. In practical applications, it demonstrates a distinct lotus leaf effect—water droplets slide off the surface effortlessly, effectively preventing moisture from penetrating into the material. This ensures stable and consistent performance even in high-humidity environments, fully reflecting its reliable waterproof and moisture-proof properties.

Our Factory

Inside our advanced production base, seamless collaboration of diversified automated lines plus ultra-short inter-workshop part transfer enable smooth, rapid material flow throughout manufacturing. This optimized layout cuts internal production logistics costs significantly and avoids extra expenses from repeated loading/unloading, greatly boosting our products' overall efficiency and cost-effectiveness.