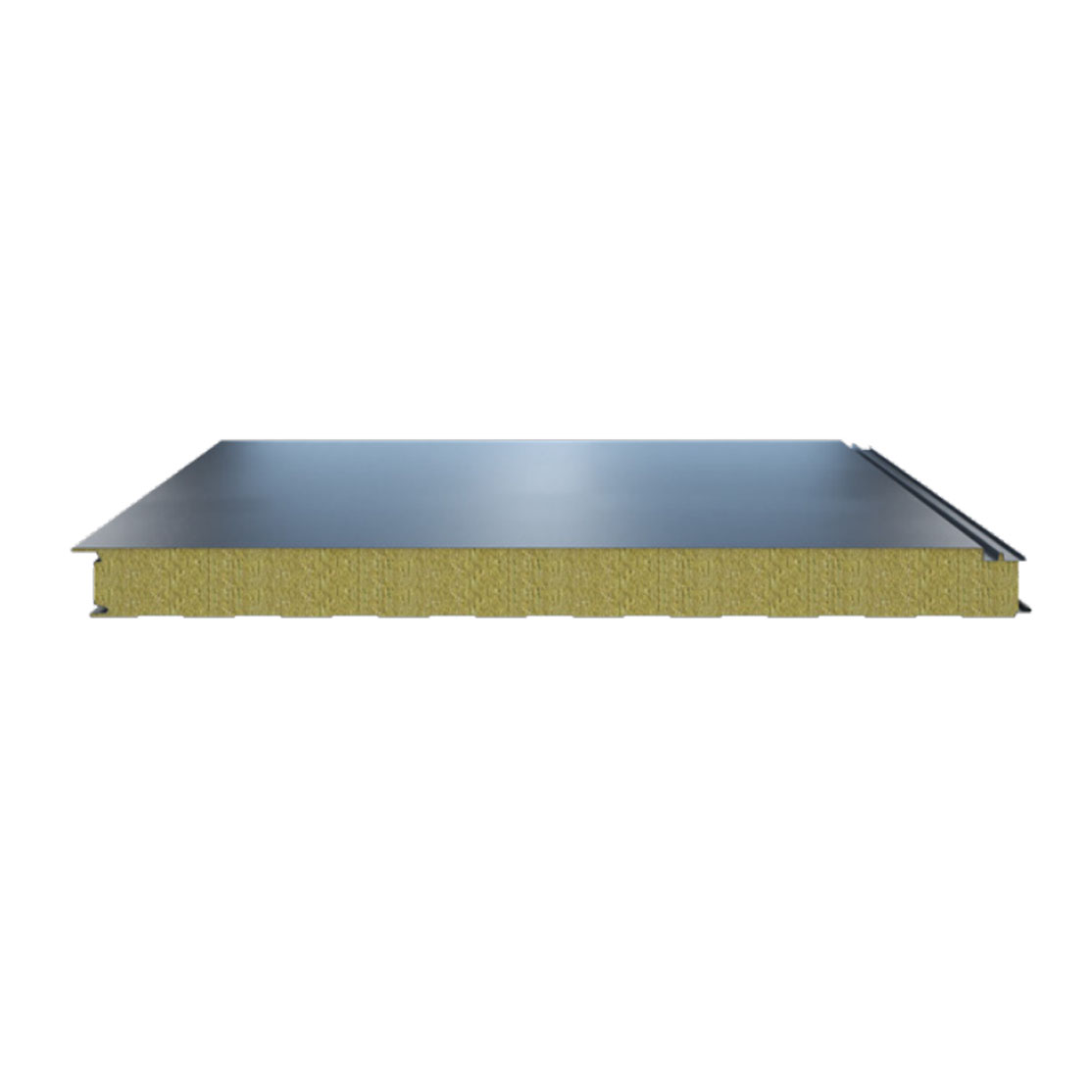

Rockwool Wall Sandwich Panel

Fire resistance: Class A non-combustible, blocks fire spread to boost building safety

Thermal insulation: Low thermal conductivity cuts heat transfer and reduces energy use

Sound insulation: Porous structure absorbs sound waves and lowers noise transmission effectively

Product Introduction

Rock wool panels with polyurethane edge sealing offer comprehensive benefits. The non-flammable rock wool core plus dedicated polyurethane edge creates a high fire rating, maximizing fire safety. Its low thermal conductivity minimizes heat loss for excellent insulation. The tight polyurethane seal blocks air, vapor and dust, effectively prolonging panel service life. Edge sealing also reinforces structural strength, reducing damage risks in transit and usage. Moreover, the panels feature a neat and smooth finish, achieving an ideal balance between practicality and aesthetics.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

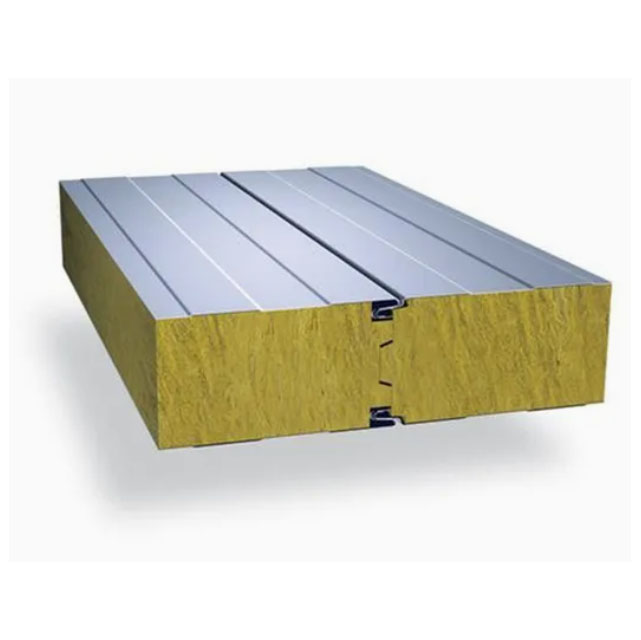

Lap Way

Composite sandwich panels come with a wide range of lapping options for different installation scenarios. Adopting concealed fasteners, the seamless lapping approach delivers an ultra-smooth, unblemished surface with no visible joints at all. For 20mm and 10mm lap joints, both applying hidden fastener designs, the visibility of the connecting seams varies distinctly to meet diverse aesthetic demands. Among all these connection ways, the tongue-and-groove lapping is the most sought-after type. It locks adjacent panels together firmly and tightly, which greatly elevates the overall structural integrity and load-bearing reliability of the whole building envelope.

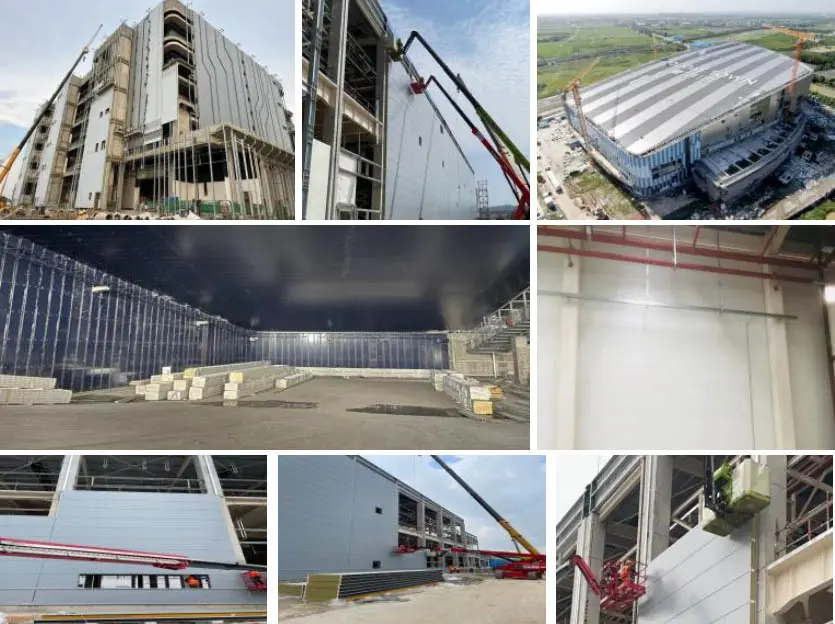

Production Workshop

Headquartered at a premium metal manufacturing base with full advanced facilities, we operate automated lines, industrial robots and precision equipment to cover the whole production cycle from raw coils to finished parts. Our large CNC centers and intelligent logistics enable high-efficiency, ultra-precise manufacturing, fully meeting mass, high-quality demands for diverse metal parts including tongue and groove plates.

Color Coated Steel Sheet Selection

Our color-coated steel sheets adopt a multi-layer structure with cold-rolled steel base, plus conversion layer, primer, intermediate and topcoat for top quality. Offering versatile coatings (2/1, 2/1M, 2/2) for corrosion/scratch resistance and process adaptability, they boast strong coating adhesion, rich colors and durable fastness, boosting building durability, safety and facade aesthetics, ideal for high-end metal cladding.

Service

We provide one-stop, full-cycle support throughout the entire purchasing process, covering every critical stage from pre-sales consultation to after-sales follow-up. Beyond core order fulfillment, we also offer professional on-site installation guidance and technical consultation tailored to your project needs, along with extended quality warranties and efficient replacement services for faulty parts. All these premium services are designed to ensure a seamless, hassle-free and worry-free experience for every client.

Construction Details