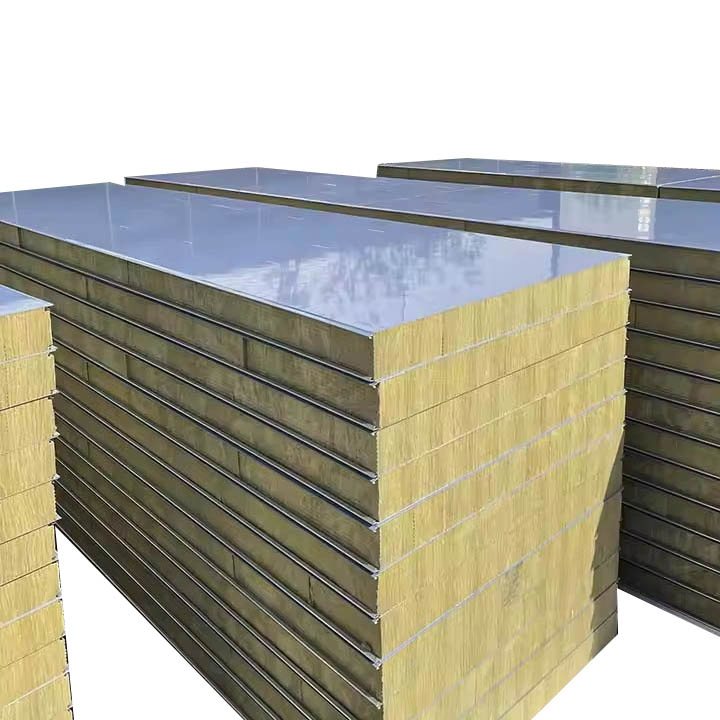

Rockwool Fire Panel

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

Rock wool fireproof sandwich panels, made of high - strength panels, are excellent building materials. Their Class A non - combustible rock wool core offers a high fire resistance limit, and they possess great fireproof, heat - insulating, and sound - insulating properties. Suitable for industrial plants, civil buildings, public facilities, and clean workshops, these panels are lightweight, strong, easy to install, eco - friendly, and durable. As a result, they are an ideal choice for fireproofing, energy conservation, and heat retention.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Application Areas

Industrial plants: used for walls and roofs, providing insulation, fire protection, and sound insulation.

Warehouses: suitable for the walls and roofs of large warehouses to improve insulation effects.

Cold storage: used for cold storage walls, with excellent insulation performance.

Public buildings: such as gymnasiums, exhibition halls, etc., to meet fire protection and sound insulation requirements.

Temporary buildings: such as temporary buildings on construction sites, quick installation and reusable.

Rockwool fire panels are an essential component in modern building design, offering superior fire resistance, thermal insulation, and acoustic performance. Commonly used in commercial, industrial, and residential applications, these panels are fabricated from mineral wool to meet stringent safety and building standards. This article provides an in-depth technical analysis of Rockwool fire panels, including engineering principles, materials, installation guidelines, performance data, and regulatory compliance.

What is a Rockwool Fire Panel?

Rockwool fire panels are composed of high-density mineral wool, also known as stone wool, which is manufactured from natural volcanic rock and basalt. The fibers are bonded to form rigid panels that are capable of withstanding extreme heat while providing insulation and acoustic performance.

Key Features

Fire Resistance: Class A1 non-combustible according to EN 13501-1

Thermal Insulation: Excellent R-values for energy efficiency

Sound Absorption: Reduces noise in commercial and industrial environments

Moisture Resistance: Retains structural integrity in humid conditions

Durability: Resistant to mechanical damage, vibration, and aging

Engineering Principles and Material Composition

Structural Components

Mineral Wool Core: Provides fireproofing, thermal insulation, and acoustic damping. Typical density ranges from 100–200 kg/m³.

Surface Facing: Panels may be coated with fire-resistant facings, such as aluminum foil, cement board, or perforated steel, enhancing durability and ease of cleaning.

Edge Design: Reinforced edges allow for secure installation and prevent gaps that may compromise fire protection.

Performance Characteristics

Thermal Conductivity: Typically 0.035–0.045 W/m·K depending on density

Fire Rating: Can achieve 60–180 minutes of fire resistance, depending on panel thickness

Moisture Absorption: Less than 1% by volume under normal conditions

Acoustic Absorption Coefficient: Up to 0.90 (NRC) for open-celled Rockwool panels

Industry Standards and Compliance

Rockwool fire panels must meet multiple international standards to ensure safety and reliability:

EN 13501-1: Fire classification of construction products

ASTM E84: Surface burning characteristics

ISO 9001: Quality management for consistent panel performance

UL 263: Fire resistance rating for structural assemblies

EN 1602: Determination of thermal insulation density and tolerance

These standards guide the selection of panel thickness, density, and surface treatment to achieve optimal fire and thermal performance.

Installation Guidelines

Substrate Preparation

Ensure walls or ceiling frameworks are level, stable, and capable of supporting panel weight.

Remove dust, debris, and moisture that could compromise adhesion or joint sealing.

Panel Installation

Positioning: Align panels accurately to maintain continuous fire barriers.

Fixing: Use mechanical fasteners, adhesive, or a combination depending on application.

Sealing: Apply fire-rated sealants at joints to prevent smoke or flame penetration.

Inspection: Perform post-installation checks for gaps, surface integrity, and fireproofing compliance.

Operational Considerations

Avoid prolonged water exposure to maintain thermal and acoustic properties

Clean using dry or lightly damp cloths; avoid harsh chemicals that may degrade facings

Conduct periodic inspections for structural integrity in high-traffic areas

Advantages of Rockwool Fire Panels

| Feature | Benefit |

|---|---|

| High Fire Resistance | Class A1 non-combustible; protects life and property |

| Thermal Insulation | Reduces energy costs in buildings |

| Acoustic Performance | Minimizes sound transmission in industrial/commercial spaces |

| Moisture Stability | Maintains shape and performance in humid environments |

| Durable and Long-Lasting | Resistant to aging, vibration, and mechanical damage |

| Environmentally Friendly | Made from natural stone and recyclable materials |

Data and Examples

Panel Thickness: 25mm to 100mm depending on fire rating requirements

Density Range: 100–200 kg/m³

Thermal Conductivity: 0.035–0.045 W/m·K

Fire Resistance Duration: 60–180 minutes for standard applications

Example Applications:

Fire-rated walls and partitions in commercial buildings

Acoustic and thermal insulation in industrial facilities

Residential fire barrier and ceiling panels

Frequently Asked Questions (FAQs)

Q1: Can Rockwool panels be used in high-rise buildings?

A: Yes, they are ideal for fire-rated walls, partitions, and ceilings in high-rise applications, meeting EN 13501-1 Class A1 requirements.

Q2: How do Rockwool panels compare to gypsum boards?

A: Rockwool panels provide superior fire resistance, thermal insulation, and acoustic performance compared to standard gypsum boards.

Q3: Are these panels safe for indoor air quality?

A: Yes, Rockwool is non-toxic, does not release harmful gases, and complies with indoor air quality standards.

Q4: Can panels be retrofitted in existing buildings?

A: Absolutely, custom-sized Rockwool panels can be installed in existing walls, ceilings, or partitions with minimal disruption.

Conclusion

Rockwool fire panels are a versatile, high-performance solution for fire safety, thermal insulation, and acoustic control. Their mineral wool core, durable surface facings, and compliance with international standards make them suitable for a wide range of residential, commercial, and industrial applications.

Call to Action

We recommend specifying Rockwool fire panels for projects that demand superior fire safety, thermal efficiency, and acoustic performance. Contact us to discuss panel specifications, fire ratings, and custom solutions for your building requirements.