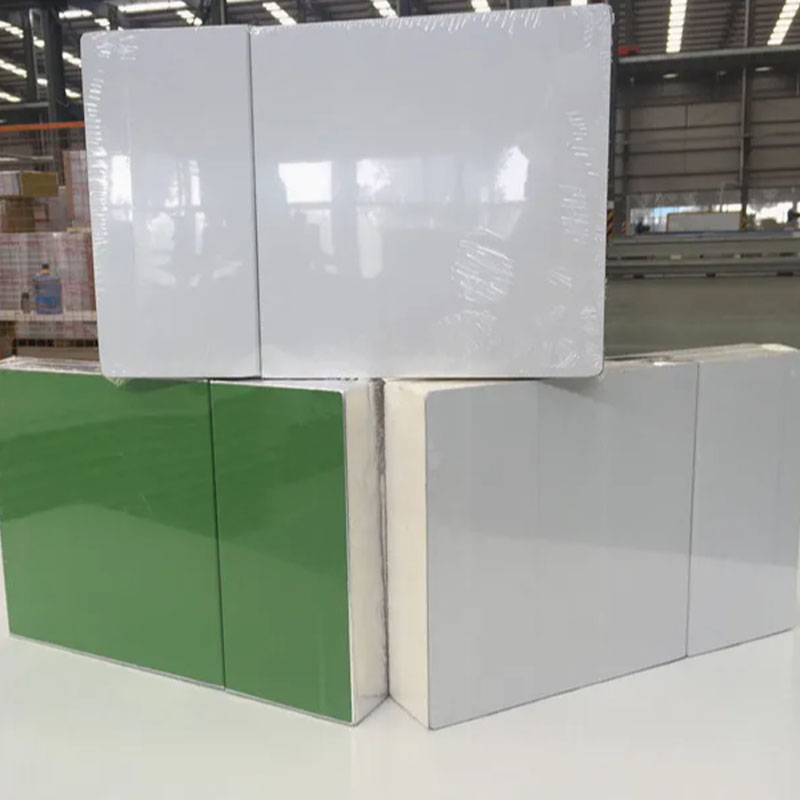

PU Panel

Waterproofness: Features a tight structure, delivering excellent waterproof performance.

Sound Insulation: If equipped with an EPS core, its porous structure effectively absorbs sound waves.

Energy Efficiency: Boasts good thermal insulation, which reduces building energy consumption and achieves energy-saving goals.

Cost-Effectiveness: Low in cost and high in cost-performance, making it suitable for large-scale applications in factories, warehouses, cold storages, temporary buildings, etc.

Product Introduction

PU Panels are high-performance building materials with excellent insulation and structural strength. Their 3-layer design (rigid PU foam core between metal facings) enables energy-efficient construction, cutting heating and cooling costs through superior thermal insulation. Lightweight in nature, they allow for easy installation and reduced structural load, while also featuring fire resistance, soundproofing, durability, weather resistance and low maintenance requirements. Suitable for industrial, commercial and residential scenarios (such as roofing, wall cladding, etc.), they are versatile enough to adapt to various architectural styles, well balancing functionality and aesthetics.

Product Specifications

PU/PIR Sandwich Panel | |

Lengths of panels | costmized(≤11.8m due to transport |

Width of panels | 500mm-1120mm |

Thickness of panels | 30/35/40/50/60/70/75/80/90/100mm |

Exterior steel thickness | 0.4-0.8mm |

Interior steel thickness | 0.4-0.6mm |

Recommend coating | PE/HDP/SMP/PVDF |

Surface finish | Emboss/Small Wave/Big Rib/Flat |

Density | 40-45 kg/m³ |

Water absorption for 24 hours | ≤1 |

Thermal conductivity | ≤0.023w/m-k |

Compressive strength | 2200kpa |

Fire proof rate | B1/B2/B3 |

Project Cases

Flow Chart of Polyurethane

The PU panel production process starts with material preparation, which includes unwinding raw materials and applying protective film. Subsequently, the materials undergo pressing to form the basic shape. Next, through spraying, preheating, and foaming procedures, the polyurethane (PU) core structure is formed. After that, the semi-finished panels are precisely guided and cut to the required dimensions, followed by a cooling stage to ensure structural stability. Finally, the finished panels are unloaded, packaged, and prepared for distribution, thus completing the efficient production cycle.

Our Factory

The factory's production lines operate with tight coordination. The short distance between workshops for parts and components enables rapid material flow. This layout not only reduces production logistics costs but also eliminates additional expenses caused by repeated loading and unloading.