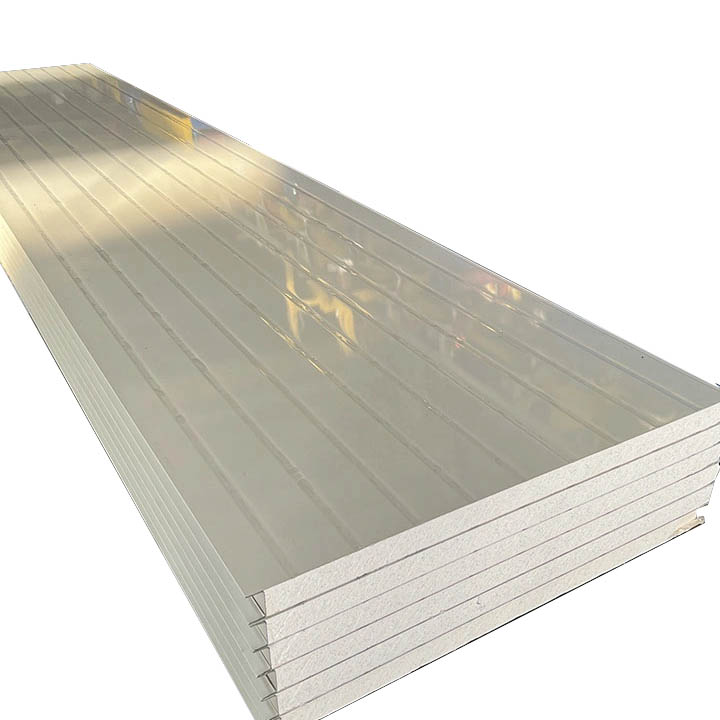

75mm EPS Sandwich Panel

Waterproof: The board structure is tight and has good waterproof performance.

Sound insulation: The porous structure of the EPS core can effectively absorb sound waves.

Energy saving: The thermal insulation performance helps to reduce building energy consumption and achieve energy saving goals.

Economical and practical: The cost is relatively low, the cost-effectiveness is high, and it is suitable for large-scale applications, such as industrial plants, warehouses, cold storage, temporary buildings, etc.

Product Introduction

When searching for a reliable and eco - friendly construction material, look no further than EPS sandwich panels. These panels are not only highly efficient in heat insulation but also demonstrate excellent fire - resistant qualities. As a result, they ensure the safety of those inside the building and create a cozy indoor atmosphere.

Product Specifications

Panel effective width | Roof:950/960mm |

Wall:950/1150mm | |

Steel sheet thickness | 0.40~0.70mm |

Panel thickness | 50/75/100/150/200mm |

EPS density | 12-14kg/m³ |

Color | As per RAL or customized |

Coating | PE,SMP,HDP,PVDF |

Steel type | PPGL,PPGI steel/Aluminum sheet/Stainless steel sheet |

Length limitaion | Max 5.9m for 20FT |

Max 11.9m for 40FT | |

Joint way | Hidden screws type |

Fire proof | B1/B2 |

Advantage | Waterproof |

Resistances of heat-transfer process | 0.035-0.05w/m·k |

Quality Assurance

The company has a top - tier material testing center laboratory equipped with over 30 pieces of professional equipment. It focuses on two tasks: comprehensively testing the physical, mechanical, and combustion properties of materials related to the enclosure system, and contributing to new product R & D. All operations follow international - standard specifications to ensure high - quality and reliable results.

Expanded Polystyrene (EPS) sandwich panels with a 75mm core thickness are widely utilized in modern construction due to their excellent thermal insulation, lightweight characteristics, and structural performance. This article provides a thorough technical overview of 75mm EPS sandwich panels, covering material composition, engineering principles, relevant standards, installation guidelines, and maintenance considerations. The objective is to equip industry professionals and project planners with essential insights to optimize application and performance.

What is a 75mm EPS Sandwich Panel?

A 75mm EPS sandwich panel consists of three layers:

Outer and Inner Skins: Typically galvanized steel sheets or aluminum, coated for corrosion resistance and durability.

Core: 75mm thick Expanded Polystyrene foam, serving as the thermal insulating layer.

Adhesive Layer: High-strength bonding agent ensuring the core adheres firmly to the metal facings.

The 75mm EPS thickness strikes a balance between thermal insulation efficiency and panel weight, suitable for walls, roofs, and cold storage applications.

Key Technical Features and Material Properties

1. Thermal Insulation

EPS has a thermal conductivity (λ) of approximately 0.032–0.038 W/m·K, providing excellent insulation.

A 75mm core thickness typically achieves a thermal resistance (R-value) around 1.97 to 2.34 m²·K/W.

Suitable for energy-efficient building envelopes complying with modern thermal performance regulations.

2. Mechanical Strength

Compressive strength of EPS ranges between 80–150 kPa, depending on density (usually 15–25 kg/m³ for construction panels).

Facings contribute to bending stiffness and impact resistance.

Panels resist wind loads, seismic forces, and mechanical impact when properly installed.

3. Fire Performance

EPS is combustible but can be enhanced with fire-retardant additives.

Compliance with fire safety standards such as ASTM E84 Class A or B, EN 13501-1, or equivalent is mandatory.

Installation must consider fire breaks and appropriate detailing to mitigate fire risks.

4. Moisture Resistance

EPS exhibits low water absorption (<1%), reducing risk of mold or deterioration.

Facings are coated to prevent moisture ingress.

Proper sealing and flashing are critical during installation to avoid water penetration.

Industry Standards and Regulatory Compliance

ASTM C578: Standard specification for rigid, cellular polystyrene thermal insulation.

EN 14509: European standard specifying self-supporting sandwich panels.

ISO 9001: Quality management certification for manufacturing processes.

Local building codes: Vary by jurisdiction and impact panel selection and installation methods.

Installation Best Practices for 75mm EPS Sandwich Panels

1. Site Preparation

Ensure structural supports meet load requirements.

Verify flatness and alignment to avoid panel stress and deformation.

2. Panel Handling

Handle panels with care to prevent damage to facings and edges.

Use suction lifters or padded clamps for large panels.

3. Fixing and Sealing

Utilize compatible fasteners and clips designed for EPS sandwich panels.

Seal joints with high-performance sealants or gaskets to ensure air and moisture tightness.

Maintain proper thermal breaks and expansion gaps per manufacturer instructions.

4. Safety Measures

Employ personal protective equipment during cutting and installation.

Manage EPS dust and waste responsibly.

Performance Data and Examples

Thermal Efficiency: Buildings insulated with 75mm EPS panels have demonstrated energy savings up to 30% in heating and cooling.

Load Capacity: Panels withstand wind pressures exceeding 2.5 kN/m², suitable for many commercial and industrial applications.

Durability: EPS panels maintain performance over 25+ years under normal environmental conditions.

Common Questions (FAQs)

Q1: Is 75mm EPS sandwich panel suitable for cold storage?

A1: Yes, its excellent thermal insulation and moisture resistance make it ideal for refrigerated warehouses and cold rooms.

Q2: How does EPS compare to other core materials like PIR or PU?

A2: EPS offers cost-effective insulation with good fire retardancy and moisture resistance but generally has lower thermal performance than PIR/PU at the same thickness.

Q3: Can EPS sandwich panels be used in seismic zones?

A3: Yes, when correctly designed and installed per structural requirements, EPS panels can perform well in seismic regions.

Q4: What maintenance is required for EPS sandwich panels?

A4: Minimal; regular inspection for seal integrity and damage, and prompt repair of any compromised areas ensure longevity.

Conclusion and Professional Recommendation

75mm EPS sandwich panels provide an optimal solution for energy-efficient, lightweight, and structurally sound building envelopes across various applications. Compliance with industry standards, proper installation, and maintenance practices ensure maximized performance and safety.

We recommend engaging qualified engineers and contractors to tailor EPS sandwich panel solutions precisely to project specifications and regulatory requirements.