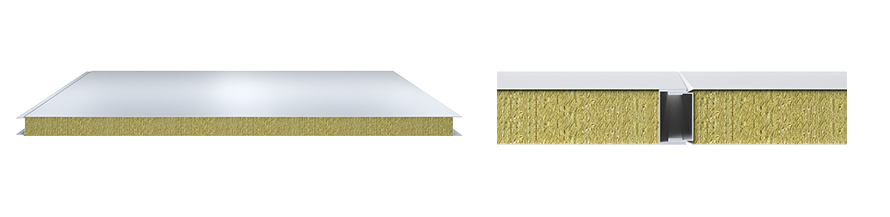

Clean Room Ceiling Panels

Hygiene & Cleanliness: Smooth, non-porous surfaces for easy cleaning. Resistant to bacteria, mold, and contaminants.

Thermal Insulation & Airtight Sealing: Maintains stable temperature and humidity, ensuring optimal conditions for sensitive processes.

Fire Resistance & Durability: Fire-resistant materials for enhanced safety, with a durable structure for long-term use.

Wide Applications: Suitable for pharmaceutical, medical, and electronic industries.

Lightweight & Modular Design: Enables quick and easy installation, with flexible layouts for customized clean room setups.

Product Introduction

Product Details

Panel Options: Color-coated panel, galvanized steel plate, stainless steel plate

Standard Colors: White, gray, crimson, silver, sea blue, and more

Recommended Coatings: PVDF, SMP, HDP, PE

Core Materials: Rock wool, PU + rock wool

Production Process: Unwinding, pressing, laying, double-track curing molding, drying, board cooling, stacking, and packaging.

| Mechanically Clean Panel | |||

| Unit:mm | |||

| Thickness | Width | Core Material | Surface Materia |

| 50-70 | 950-1150 | Rock Wool Board Magnesium Sulfate Board Silicon Rock Board Foam Board Paper Honeycomb Board Magnesium Oxide Grid Board | Color-coated Steel Plate or Stainless Steel Plate Coating: Z/AZ/AZM Coating: PE/PVDF/HDP/SMP Functions: Antistatic / Antibacterial |

Brand Advantages

Our company takes pride in its vast network of partners, maintaining long-standing collaborations with industry-leading enterprises spanning construction, manufacturing, technology, logistics, and other sectors. By synergizing resources from both global brands and local suppliers, we fuel innovation to provide clients with more efficient and dependable solutions.