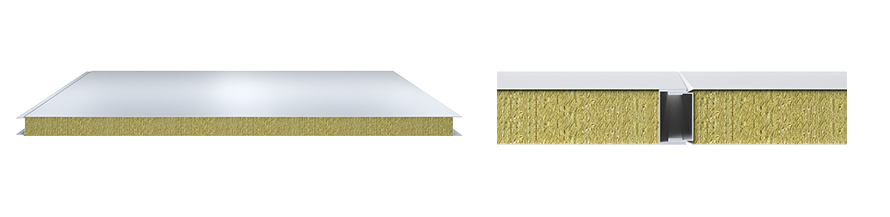

Mechanically Clean Panel

Hygiene & Cleanliness: Smooth, non-porous surfaces for easy cleaning. Resistant to bacteria, mold, and contaminants.

Thermal Insulation & Airtight Sealing: Maintains stable temperature and humidity, ensuring optimal conditions for sensitive processes.

Fire Resistance & Durability: Fire-resistant materials for enhanced safety, with a durable structure for long-term use.

Wide Applications: Suitable for pharmaceutical, medical, and electronic industries.

Lightweight & Modular Design: Enables quick and easy installation, with flexible layouts for customized clean room setups.

Product Introduction

The Mechanically Clean Panel (MCP) is a high-performance building material integrating fire resistance, thermal insulation, and contamination control. With a smooth, non-porous glass magnesium surface and rock wool core, it offers hygienic performance, energy efficiency, and soundproofing, ideal for pharmaceutical, medical, and electronic sectors. Its lightweight, durable design allows quick installation, reducing costs, while moisture resistance ensures long-term use in challenging environments, meeting modern sustainable construction needs.

Product Details

Panel Options: Color-coated panel, galvanized steel plate, stainless steel plate

Standard Colors: White, gray, crimson, silver, sea blue, and more

Recommended Coatings: PVDF, SMP, HDP, PE

Core Materials: Rock wool, PU + rock wool

Production Process: Unwinding, pressing, laying, double-track curing molding, drying, board cooling, stacking, and packaging.

| Mechanically Clean Panel | |||

| Unit:mm | |||

| Thickness | Width | Core Material | Surface Materia |

| 50-70 | 950-1150 | Rock Wool Board Magnesium Sulfate Board Silicon Rock Board Foam Board Paper Honeycomb Board Magnesium Oxide Grid Board | Color-coated Steel Plate or Stainless Steel Plate Coating: Z/AZ/AZM Coating: PE/PVDF/HDP/SMP Functions: Antistatic / Antibacterial |

About Coating Structure