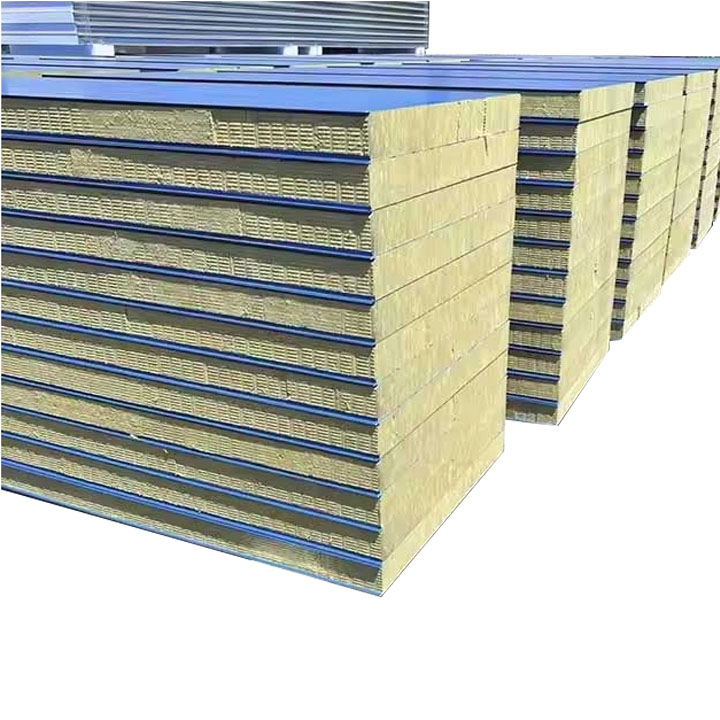

Blue Rock Wool Board

Fire resistance: Rock wool is made of minerals such as basalt and is a Class A non-combustible material. It can effectively prevent the spread of fire and improve building safety.

Thermal insulation: Rock wool has a low thermal conductivity, which can effectively reduce heat transfer, improve building insulation effect, and reduce energy consumption.

Sound insulation: The porous structure of rock wool can absorb sound waves and reduce noise transmission, and is suitable for places where sound insulation is required.

Corrosion resistance: Rock wool has stable chemical properties, is resistant to acid and alkali corrosion, is suitable for a variety of environments, and has a long service life.

High compressive strength: Rock wool has a tight structure and good compressive resistance, and is suitable for occasions that require load-bearing.

Product Introduction

Rock wool fireproof sandwich panel is a building material composed of high-strength panels, which has excellent fireproof, heat-insulating and sound-insulating properties. Its rock wool core material is a Class A non-combustible material with a high fire resistance limit. It also has good heat insulation and sound-absorbing effects. It is suitable for industrial plants, civil buildings, public facilities and clean workshops. The panel is light, high-strength, easy to install, environmentally friendly and durable, and is an ideal choice for fireproof isolation, energy saving and heat preservation.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Application Areas

Industrial plants: used for walls and roofs, providing insulation, fire protection, and sound insulation.

Warehouses: suitable for the walls and roofs of large warehouses to improve insulation effects.

Cold storage: used for cold storage walls, with excellent insulation performance.

Public buildings: such as gymnasiums, exhibition halls, etc., to meet fire protection and sound insulation requirements.

Temporary buildings: such as temporary buildings on construction sites, quick installation and reusable.

Blue Rock Wool Board is a high-performance thermal insulation material widely used in construction, industrial applications, and fireproofing solutions. Known for its superior thermal resistance, sound absorption, and fire retardant properties, Blue Rock Wool Board meets stringent industry standards and regulatory requirements. This article provides an in-depth technical overview, exploring its material composition, engineering principles, standards compliance, installation considerations, and practical applications.

What is Blue Rock Wool Board?

Blue Rock Wool Board is an engineered insulation board manufactured from natural basalt rock fibers. The “blue” designation refers to the specific color coding used by some suppliers to indicate this grade of rock wool product. It is fabricated into rigid or semi-rigid boards that provide excellent thermal and acoustic insulation while maintaining fire resistance.

Key Properties and Material Composition

Material: Basalt rock fibers, bonded with inorganic binders for structural integrity.

Density: Typically ranges from 100 to 180 kg/m³, balancing insulation and mechanical strength.

Thermal Conductivity: Approximately 0.035 – 0.045 W/m·K, offering effective thermal resistance.

Fire Resistance: Non-combustible withstanding temperatures over 1000°C without structural degradation.

Sound Absorption: NRC (Noise Reduction Coefficient) typically above 0.75, effective in noise control applications.

Moisture Resistance: Hydrophobic treatment enhances water repellency, reducing moisture absorption.

Engineering Principles

Blue Rock Wool Board’s performance is grounded in its fibrous microstructure:

Thermal Insulation: The randomly oriented fibers trap air pockets, minimizing conductive and convective heat transfer.

Fireproofing: Inorganic composition prevents ignition and limits heat transfer during fire exposure.

Acoustic Damping: Fiber network dissipates sound energy, reducing reverberation and noise transmission.

Mechanical Stability: Board rigidity enables installation in walls, ceilings, and mechanical equipment insulation without sagging or deformation.

Industry Standards and Regulatory Compliance

Blue Rock Wool Boards comply with key international and regional standards such as:

EN 13162: Specifies thermal insulation products for buildings, including rock wool boards.

ASTM C612: Standard specification for mineral fiber block and board thermal insulation.

ISO 9001: Quality management standard ensuring consistent product manufacturing.

Fire Safety Standards: Compliance with NFPA 285 and UL 723 for flame spread and smoke development.

Environmental Certifications: Many Blue Rock Wool products are certified for low VOC emissions and sustainable manufacturing.

Applications

Building Insulation: External wall insulation, cavity walls, and roofing systems.

Fire Protection: Passive fire barriers in commercial and industrial buildings.

Acoustic Panels: Used in auditoriums, studios, and offices for sound control.

HVAC Systems: Insulation of ducts and mechanical equipment to improve energy efficiency.

Industrial Equipment: Thermal insulation in power plants, refineries, and petrochemical facilities.

Installation and Handling Considerations

Surface Preparation: Ensure substrates are clean, dry, and smooth before application.

Cutting and Shaping: Boards can be cut with standard insulation knives or saws; precision is key for tight fits.

Fixing Methods: Mechanical fasteners, adhesives, or framing systems depending on application.

Safety Precautions: Use personal protective equipment (PPE) such as gloves, masks, and goggles to prevent irritation from fibers.

Moisture Control: Avoid prolonged exposure to water; utilize vapor barriers where necessary.

Practical Example

In a recent commercial building retrofit, Blue Rock Wool Boards were installed as part of the external insulation system. The project achieved a reduction in heat loss by 35% and significantly improved fire resistance ratings, contributing to energy savings and occupant safety compliance.

Frequently Asked Questions (FAQs)

Q1: How does Blue Rock Wool Board compare to fiberglass insulation?

Blue Rock Wool offers superior fire resistance and better sound absorption, while fiberglass may have lower cost but is less fire resistant.

Q2: Is Blue Rock Wool Board safe for indoor use?

Yes, it is non-toxic and certified low in volatile organic compounds (VOCs), making it safe for indoor environments.

Q3: Can Blue Rock Wool Board be used outdoors?

It can be used in protected outdoor applications but typically requires a weather-resistant barrier.

Q4: What is the typical lifespan of Blue Rock Wool insulation?

With proper installation, it can last 30 years or more without significant degradation.

Q5: How should I dispose of Blue Rock Wool Board?

Follow local regulations; generally, it can be disposed of as construction waste or recycled if facilities exist.

Conclusion and Call to Action

Blue Rock Wool Board is a robust and versatile insulation material that excels in thermal management, fire protection, and acoustics. Its compliance with international standards ensures reliability and performance across a range of applications. For engineers, architects, and contractors seeking high-quality insulation solutions, careful consideration of material specifications and installation best practices is essential.

Contact us to learn how We can provide certified Blue Rock Wool Board tailored to your project needs, backed by expert technical support and competitive factory pricing. Invest in safety, efficiency, and sustainability with our premium insulation solutions.