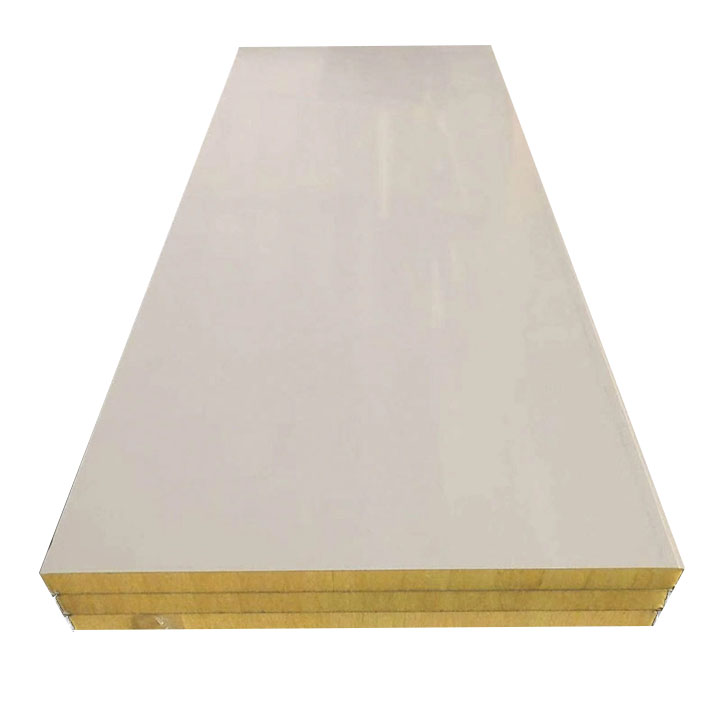

Moisture Proof Sandwich Panel

Fireproof: Glass wool is a non-combustible material, and the sandwich panel has good overall fireproof performance.

Corrosion resistance: The metal panel has been treated with anti-corrosion, has strong corrosion resistance, and extends its service life.

Health: Glass wool is an inorganic material and does not contain harmful substances.

Beauty: The panel color and surface treatment are diverse, meeting the aesthetic requirements of different architectural styles.

Economical and practical: Superior comprehensive performance, long service life, low maintenance cost, and high cost performance.

Product Introduction

The glass wool sandwich panel is a versatile building material known for its exceptional thermal insulation, making it ideal for energy-efficient construction projects. It provides superior fireproof performance, ensuring safety in both residential and commercial spaces. With excellent acoustic insulation, this panel effectively reduces noise, making it a perfect choice for offices, studios, and schools.

Product Specifications

Product name | Glass Wool Sandwich Panel |

Effective width | Wall panel: 950mm/1000mm/1150mm |

Roof panel :1000mm | |

Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

Length | Less than 11.8m |

Density | 64 KG/m3 |

Steel sheet thickness | 0.4-0.7mm |

Thermal Conductivity | <0.023 |

Color | RAL |

Fireproof Grade | White, gray, crimson, silver, sea blue, customized |

Application | Sandwich Panel for Steel Strucure |

Features | Soundproof, Waterproof, Heat insulation, Seismic Resistance |

Product Details

Panel: color-coated panel, galvanized steel plate, stainless steel plate

Standard colors: white gray / crimson / silver / sea blue, etc.

Recommended coating: PVDF / SMP / HDP / PE

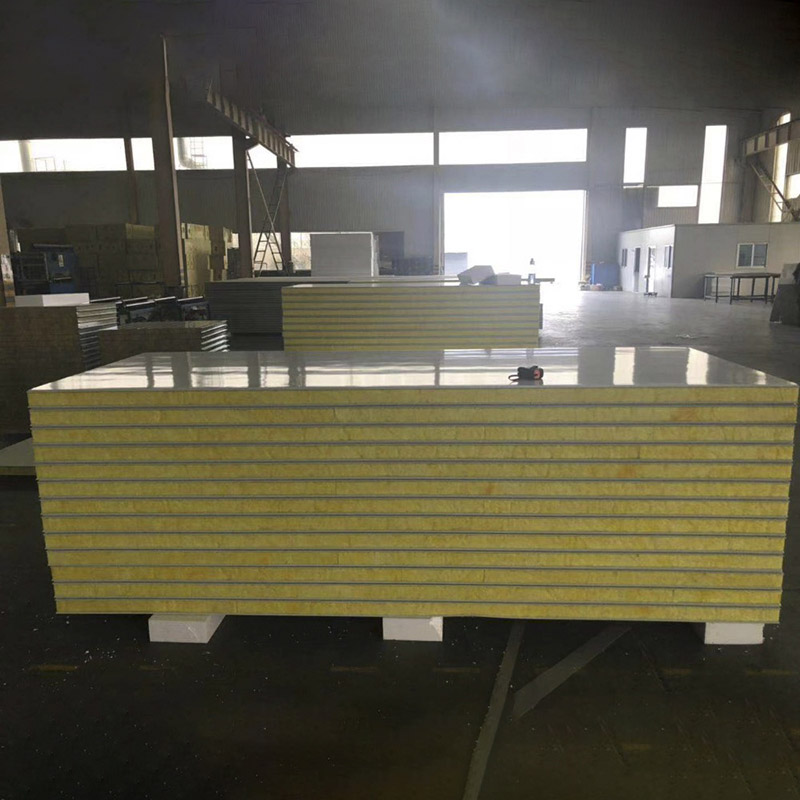

Production process: unwinding, pressing, laying, double-track curing molding, drying board cooling, stacking, packaging

Quality Assurance

The company has a first - class material testing center lab with over 30 pieces of pro equipment. It serves two main functions: comprehensively testing properties of raw, auxiliary materials and finished products in the enclosure system, and aiding new product R & D. All work follows international - standard specs for high - quality results.

Moisture proof sandwich panels are advanced multilayered building materials designed to prevent moisture intrusion while maintaining structural rigidity, thermal insulation, and environmental resistance. These panels are essential in environments where condensation, high humidity, or water ingress pose risks to building longevity, energy efficiency, and indoor air quality.

This article delivers a full engineering perspective on the construction, materials, performance data, compliance, and application of moisture-resistant sandwich panels—ideal for architects, engineers, and facility planners.

Table of Contents

What Is a Moisture Proof Sandwich Panel?

Material Composition and Moisture-Blocking Mechanism

Performance Specifications and Technical Properties

Standards and Regulatory Compliance

Applications Across Industries

Installation and Maintenance Considerations

Frequently Asked Questions (FAQs)

Conclusion & Professional Call to Action

1. What Is a Moisture Proof Sandwich Panel?

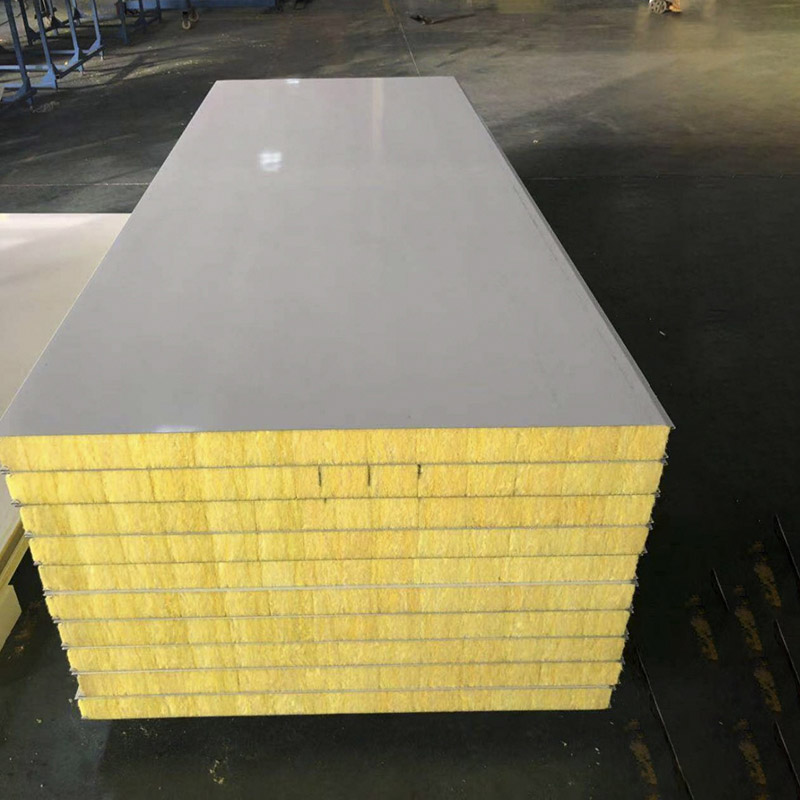

A moisture proof sandwich panel is a multilayer construction panel that includes outer facings, an insulating core, and a vapor-resistant barrier. Its primary function is to resist vapor diffusion, water absorption, and mold formation while ensuring mechanical performance.

General Panel Structure:

Outer Face: Pre-coated steel, aluminum, fiberglass-reinforced plastic (FRP), or HPL (high-pressure laminate)

Core: Polyurethane (PU/PIR), rock wool, XPS, or EPS foam with closed-cell structure

Moisture Barrier Layer: Aluminum foil, polyethylene film, or sealed joints with hydrophobic sealants

2. Material Composition and Moisture-Blocking Mechanism

| Layer | Material | Moisture-Resistant Function |

|---|---|---|

| External Skin | Color-coated galvanized steel / aluminum / FRP / HPL | Physical barrier to rain, humidity, and UV rays |

| Core Insulation | PU, PIR, or XPS with ≤2% water absorption | Retains R-value under wet conditions |

| Internal Liner | Waterproof film / foil / melamine-impregnated paper | Acts as a vapor barrier |

| Sealant | PU foam or silicone | Prevents capillary leakage through joints |

3. Performance Specifications and Technical Properties

| Property | Typical Value | Test Standard |

|---|---|---|

| Water Absorption | ≤2% (PU), ≤1% (XPS) | ISO 2896 / ASTM C209 |

| Vapor Transmission Rate | ≤0.01 g/m²·24h | ASTM E96 / EN 12086 |

| Thermal Conductivity | 0.020–0.040 W/m·K | ISO 8301 |

| Compressive Strength | ≥150 kPa (PU), ≥50 kPa (EPS) | EN 826 |

| Fire Rating | B1 (DIN 4102), B-s1,d0 (EN 13501-1) | Fire classification |

| Dimensional Stability | ±2 mm/m | ISO 2796 |

| Surface Corrosion Resistance | ≥750h Salt Spray (with PVDF coating) | ASTM B117 |

4. Standards and Regulatory Compliance

To ensure performance in sensitive environments, moisture-proof sandwich panels must comply with:

International Standards:

EN 14509: Self-supporting insulated sandwich panels

EN ISO 11925-2 / EN 13823: Reaction to fire tests

ASTM C518: Steady-state thermal transmission

DIN 4102 / EN 13501-1: Fire performance

CE Marking: Structural safety and environmental compliance

RoHS / REACH: Non-toxicity of materials

LEED / BREEAM: Green building standards (on request)

✅ Eco Compliance: Many manufacturers now offer CFC-free foam and recyclable metal skins to support environmental building certifications.

5. Applications Across Industries

🏭 Industrial & Commercial

Cold storage warehouses

Hygienic food processing units

Pharmaceutical cleanrooms

Bottling plants and dairy facilities

🏥 Medical & Institutional

Hospital isolation rooms

MRI & CT scan suites (moisture-controlled)

Lab walls and ceilings

🏗️ Residential & Prefabricated Buildings

Bathroom modules

Rooftop extensions

Prefab homes in humid climates

🚢 Marine & Offshore

Ship cabins, offshore living quarters

Containerized mobile laboratories or clinics

6. Installation and Maintenance Considerations

Installation Guidelines:

Ensure tight joint sealing using PU foam or waterproof tape

Panels must be installed with a minimum slope of 3% in roofing to prevent ponding

Cam-lock, tongue & groove, or hidden fastener systems are ideal for airtightness

Maintenance:

Wash panels with neutral pH detergents; avoid high-pressure washing directly at joints

Perform bi-annual checks on sealant condition and edge caps

Replace damaged or delaminated panels immediately to maintain vapor barrier integrity

Storage & Handling:

Store flat, covered, and off the ground

Avoid prolonged UV exposure of uncoated foam cores

7. Frequently Asked Questions (FAQs)

Q1: Are PU-core sandwich panels fully waterproof?

They are moisture resistant, not 100% waterproof. When installed with proper sealing, they can withstand high-humidity environments and splashing but should not be submerged.

Q2: Can moisture-proof panels be used as roofing?

Yes, with appropriate slope and UV-stable coating (e.g., PVDF), many panels are certified for roofing use.

Q3: What's the difference between rock wool and PU in moisture resistance?

PU and PIR offer lower water absorption but rock wool has superior fire resistance. For humid environments with high fire safety needs, rock wool with waterproof lamination is recommended.

Q4: Do these panels offer sound insulation as well?

Yes, PU and PIR cores typically provide 20–28 dB sound attenuation. Rock wool cores can reach 30+ dB.

Q5: Are custom sizes and finishes available?

Absolutely. Panels can be produced in custom widths (950–1200mm), lengths (up to 12m), and surface coatings (PVDF, PVC, HPL, stainless steel).

8. Conclusion & Call to Action

Moisture proof sandwich panels are a vital element in modern construction, combining advanced barrier protection, thermal insulation, and lightweight design. Whether used in cold chain logistics, cleanroom architecture, or coastal housing, these panels offer long-term durability, low maintenance, and regulatory compliance.