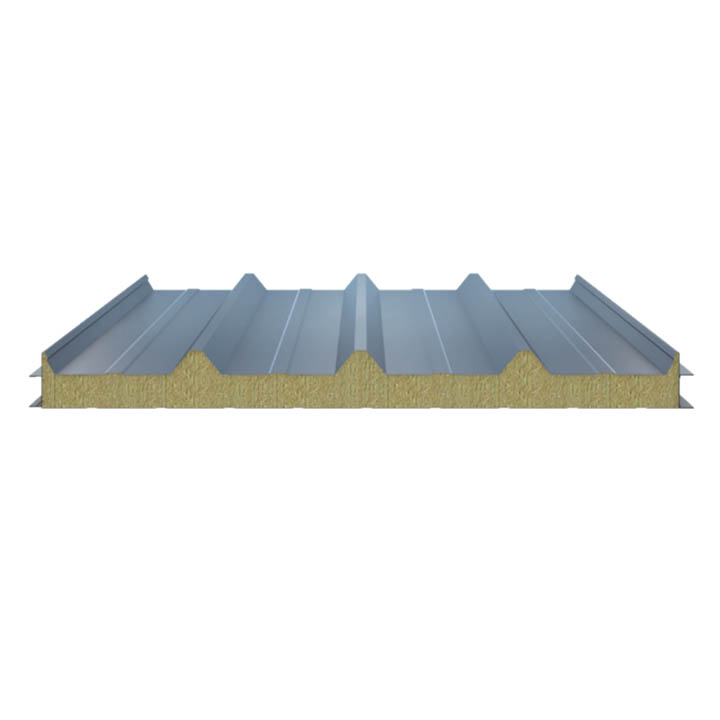

Color Steel Rock Wool Board

Thermal Insulation: Excellent energy-saving performance, maintaining comfortable indoor temperatures.

Fire Resistance: Rock wool core resists fire, enhancing building safety.

Sound Insulation: Effective noise reduction, improving acoustics.

Durability: Strong, weather-resistant, and long-lasting.

Easy Installation: Lightweight, quick to install, and low-maintenance.

Product Introduction

Rock wool fireproof sandwich panels, made of high - strength parts, are top - tier building materials. With a Class A non - combustible rock wool core, they offer great fire resistance. They also provide good heat insulation, sound - absorption, and are lightweight, strong, easy to install, eco - friendly, and durable. Suitable for industrial plants, civil buildings, public facilities, and clean workshops, they're ideal for fireproof isolation, energy - saving, and heat - preservation.

Product Specifications

Effective width | Wall panel: 950mm |

Roof panel: 960mm | |

Material | Color Steel Sheet |

Rock wool board | |

Structure | Upper and lower layer: color steel sheet |

Middle layer: Rock wool board | |

Thickness | Color steel sheet: 0.5~0.8mm |

Rock wool board: 50mm, 75mm, 100,150mm | |

Rock wool Density | 120kg/m³ |

Lifetime | 20~35 years |

Features | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly, |

Color steel rock wool board is a high-performance, composite building material widely used for thermal insulation, fire protection, and acoustic control in industrial and commercial construction. Engineered by bonding a core of rock wool (mineral wool) between color-coated steel sheets, this sandwich panel delivers exceptional durability, structural rigidity, and environmental resistance.

This SEO-optimized article provides a deep technical dive into the composition, manufacturing process, engineering principles, regulatory standards, and installation best practices for color steel rock wool boards.

What Is a Color Steel Rock Wool Board?

A color steel rock wool board is a prefabricated sandwich panel consisting of:

Core Material: Rock wool (mineral wool made from basalt)

Outer Layers: Pre-coated galvanized steel sheets (PPGI)

Bonding Method: High-adhesion polyurethane or phenolic adhesives under heat and pressure

Surface Treatment: Polyester, PVDF, or SMP paint for corrosion resistance

The combination results in a panel that is fire-resistant, thermally stable, sound-insulating, and suitable for envelope construction, partitioning, and roofing.

Core Features and Engineering Advantages

| Property | Performance |

|---|---|

| Fire Resistance | ≥2 hours (Class A, non-combustible) |

| Thermal Conductivity | 0.035–0.045 W/m·K |

| Sound Insulation (Rw) | ≥25 dB (depending on thickness) |

| Density of Rock Wool Core | 80–150 kg/m³ |

| Surface Steel Thickness | 0.4–0.8 mm (each side) |

| Overall Panel Thickness | 50 mm – 200 mm |

| Compressive Strength | ≥0.15 MPa |

| Bending Strength (EN 14509) | ≥0.5 kN/m² (span dependent) |

Engineering Principles Behind the Design

The structural and insulation performance of color steel rock wool board is governed by the sandwich panel engineering model, which follows these principles:

Load Distribution: The steel face sheets resist bending stresses, while the rock wool core provides shear resistance.

Fireproofing: Rock wool, made from melted basalt, is non-combustible and retains dimensional stability up to 1000°C.

Thermal Insulation: The fine fiber structure of mineral wool traps air, reducing heat conduction.

Acoustic Control: The porous structure dissipates sound energy through internal friction.

Corrosion Resistance: Pre-painted galvanized steel resists moisture, UV radiation, and chemical attack.

Applicable Industry Standards and Certifications

Material & Performance Standards:

EN 13501-1: Fire classification of construction products (Class A1/A2)

EN 14509: Self-supporting double skin metal faced insulating panels

GB/T 23932-2009: Chinese standard for sandwich panels with metal skins

ASTM C665: Specification for mineral-fiber blanket insulation

ISO 1182 / ISO 1716: Reaction to fire testing

Environmental and Safety Compliance:

ISO 9001: Quality management systems

ISO 14001: Environmental management

RoHS/REACH: Compliance for hazardous substances

FM Approved / CE Marking: Where required for export or specialized applications

Common Applications

| Sector | Use Case |

|---|---|

| Industrial Plants | Insulated walls and ceilings |

| Cleanrooms | Partition panels with anti-static coatings |

| Warehouses | Roof and wall cladding with fire safety |

| Commercial Spaces | Acoustic partitions in shopping centers |

| Public Infrastructure | Transport hubs, schools, hospitals |

Manufacturing Process Overview

Preparation of Steel Coils: Galvanized and color-coated coils are cut and cleaned.

Rock Wool Cutting: Sliced to fit the specified panel thickness and density.

Adhesive Application: Heat-resistant glue applied to both steel and core.

Lamination: High-pressure roll forming compresses the layers together.

Edge Treatment: Tongue-and-groove or flat joint options.

Curing and Cutting: Final product cured, cooled, trimmed, and packaged.

Installation Guidelines and Best Practices

Substrate Requirements:

Steel or concrete framework with level support

Structural fasteners rated for wind load and seismic stress

Panel Installation:

Use mechanical lifting devices for long panels

Align using tongue-and-groove or interlock edges

Seal joints with non-combustible silicone sealant

Fix with self-drilling screws with EPDM washers at specified intervals

Operation & Maintenance:

Inspect regularly for paint peeling, joint movement, or fastener corrosion

Clean using non-abrasive detergent; avoid acidic solutions

Retouch damaged coatings to prevent steel corrosion

Environmental and Lifecycle Considerations

Rock wool core is made from natural basalt and slag, offering:

High recyclability

Zero ozone depletion potential

Excellent lifecycle carbon performance

Color-coated steel can be recycled fully, making the product a strong candidate for LEED or BREEAM certification in green building projects.

Frequently Asked Questions (FAQs)

Q1: What makes rock wool better than PU or EPS core materials?

A: Rock wool offers superior fire resistance, maintains insulation under high temperatures, and provides better sound absorption than polyurethane (PU) or expanded polystyrene (EPS).

Q2: Can color steel rock wool boards be used in cold climates?

A: Yes. With thermal conductivity as low as 0.035 W/m·K, these boards are excellent for cold storage, northern climates, and energy-efficient construction.

Q3: How long do these panels last?

A: With proper installation and minimal maintenance, 25–35 years of service life is typical under industrial conditions.

Q4: Are there eco-friendly variants available?

A: Yes. Panels using bio-soluble rock wool, low-VOC adhesives, and recycled steel are increasingly available.

Q5: What fire ratings are typically achieved?

A: When tested to EN 13501-1, most panels meet Class A2-s1, d0, indicating excellent fire performance with minimal smoke and no flaming droplets.